212

Series Tooling Alcoa Fastening Systems

14

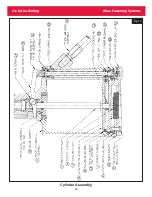

Fig. 3.4

F

ILLING AND BLEEDING PROCEDURE

(

CONT

.)

7. Stand tool upright on bench. While

actuating the trigger slowly (20 - 30

cycles), bend fill bottle at right angles to

tool - - see

FIGURE 3.4

. Observe that air

bubbles emerge from tool. When bubbles

are no longer observed, cycling may be

discontinued.

8. When trigger is released, pull piston

returns to idle position (full forward).

Disconnect tool from airline with piston

full forward.

9. Lay tool on its side. Remove fill bottle.

Top off fluid in fillport. Install bleed plug

and tighten with screwdriver.

10. Connect airline to tool. There is a choice

of two procedures for measuring the

stroke - - with and without a stall-nut - -

see appropriate section and follow the

selected procedure. If stroke is less than

specified, remove bleed plug and top off

fluid. Reinstall bleed plug.

11. Install two fasteners to check function

and installation in a single stroke, or

cycle tool with stall nut fully threaded

onto piston. Measure stroke again.

Remove plug and top off fluid. Reinstall

plug and cycle again - - measure again.

Continue this process until stroke meets

minimum requirements.

Summary of Contents for ALCOA 212

Page 1: ...11 09 2009 HK838 INSTRUCTION MANUAL 212 PNEUDRAULIC INSTALLATION TOOL...

Page 2: ......

Page 4: ...This page is intentionally blank...

Page 8: ...212 Series Tooling Alcoa Fastening Systems 6 Fig 1 Outline Drawing...

Page 23: ...212 Series Tooling Alcoa Fastening Systems 21 Fig 5 Handle Assembly...

Page 25: ...212 Series Tooling Alcoa Fastening Systems 23 Fig 10 Piston and Gland Removal...

Page 26: ...212 Series Tooling Alcoa Fastening Systems 24 Fig 11 Piston and Gland Insertion assembly...

Page 27: ...212 Series Tooling Alcoa Fastening Systems 25 Fig 12 Gland Assembly...

Page 28: ...212 Series Tooling Alcoa Fastening Systems 26 Fig 13 Cylinder Assembly...