212

Series Tooling Alcoa Fastening Systems

15

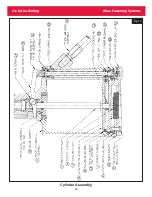

Fig. 4.1

Fig. 4

To measure stroke of tool with stall-

nut threaded onto piston:

1. Disconnect tool from airline -- remove nose

from tool.

2

With piston fully forward (end of RETURN

stroke), bottom the stall-nut on piston. Back

stall-nut off five (5) turns.

3. Cycle tool and hold trigger depressed - -

this keeps piston fully to the rear and at end

of PULL stroke. Thread stall-nut back onto

piston until it contacts stop.

4. Release trigger. Stall-nut wilI move forward

with piston. See

FIGURE 4

and measure “X”

dimension. This is the tools stroke.

5. If stroke is less than .812, refer to appropri-

ate previous section. Follow filling and top-

ping off instructions

To measure stroke of tool without

stall-nut:

1. Disconnect tool from airline - - remove nose

from tool.

2. With piston fully forward (end of RETURN

stroke), measure and record “X” dimension - -

see

FIGURE 4.1

.

3. Hold trigger depressed. Piston is now fully to

the rear and at end of PULL stroke. Measure

and record “Y” dimension.

4. Subtract “X” dimension from “Y” dimension.

5. If stroke is less than .812, refer to appropriate

previous section. Follow filling and topping off

instructions.

H

OW TO MEASURE STROKE

Summary of Contents for ALCOA 212

Page 1: ...11 09 2009 HK838 INSTRUCTION MANUAL 212 PNEUDRAULIC INSTALLATION TOOL...

Page 2: ......

Page 4: ...This page is intentionally blank...

Page 8: ...212 Series Tooling Alcoa Fastening Systems 6 Fig 1 Outline Drawing...

Page 23: ...212 Series Tooling Alcoa Fastening Systems 21 Fig 5 Handle Assembly...

Page 25: ...212 Series Tooling Alcoa Fastening Systems 23 Fig 10 Piston and Gland Removal...

Page 26: ...212 Series Tooling Alcoa Fastening Systems 24 Fig 11 Piston and Gland Insertion assembly...

Page 27: ...212 Series Tooling Alcoa Fastening Systems 25 Fig 12 Gland Assembly...

Page 28: ...212 Series Tooling Alcoa Fastening Systems 26 Fig 13 Cylinder Assembly...