212

Series Tooling Alcoa Fastening Systems

19

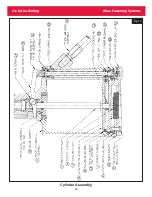

See applicable illustrations.

Clean all components with mineral spirits, and

inspect for wear or damage. Replace as neces-

sary.

Always replace all seals and back-up

rings on/in disassembled components.

Use

O-rings, QUAD rings and back-up rings supplied

in Service Kit, 212KlT - - see

NOTES

. Smear

LUBRIPLATE 13OAA or PARKER-O-LUBE on

seals.

1. If bushings are being replaced:

Note:

Use LOCTITE 609, (Huck 503377) on

bushings when pressing into cylinder.

Use an arbor press. Place chamfered end of

Upper Bushing (58) in top of Cylinder (24).

Carefully press bushing squarely into cylinder.

Repeat procedure for Lower Bushing (59).

2. After new bushings are installed they may

have to be reamed, lapped, and honed to

bring their inside diameters to size for correct

fit and alignment with throttle valve.

3. Position Cable Assembly (21) in Trigger (20)

slot and push Linkage Pin (19) through holes

in trigger and cable assembly. Position

assembled trigger in Handle (3) and push

Slotted Pin (18) through holes in handle and

trigger.

4. Hold Head/handle (3) securely with lower end

pointing up. Turn Cylinder (24) bottom up, and

line up cylinder pin with handle hole. Press

Handle onto cylinder.

5. Assemble Gland Assembly - - see

FIGURE

12

Note:

Cup of POLY-SEAL (32) must face

toward top of tool when installed in Gland

(29).

Use new replacement POLY-SEAL (32),

Spacer and SPIRO-LOX Retaining Ring (34).

6.

CAUTION: DO NOT install Throttle Arm

Pivot Shoulder Screw (23) before Gland

(29) is installed to avoid damage to these

parts.

Apply VIBRATITE (Huck 505125) to threads

of Gland Assembly (29) - - follow directions on

container. Screw gland into head/handle.

Using 1 3/8 socket wrench, tighten gland to

90 ft. lbs. + 10 lbs.

7. Push Bumper (38) firmly over Gland (29) - -

face of bumper with two slots must face

toward bottom of tool.

8. Carefully press assembled Piston (39). Rod

(41). Nut (42), and QUAD Ring (40) into

Cylinder/handle (3) through Gland Assembly,

116134.

9. Push Cylinder Head (39) squarely into

head/handle taking care not to damage O-ring

(44). Install Retaining Ring (45).

10. Position O-ring (46) and Muffler (47) on center

of Cylinder Head (43). Position Gasket (48)

on cylinder and Spring (28) in lower bushing.

11. Carefully position Muffler End Cap (50) on

cylinder - - be certain that muffler is properly

positioned in recess of muffler end cap.

12. Hold end cap down and screw in three

Button Head Screws (51) and tighten with 1/8

hex key.

13. Place tool upright on level surface. Push

Throttle Valve (52) into cylinder.

14. Place ball end of Throttle Cable (21) in end of

Throttle Arm (22).

15. Slide throttle arm into slot on Throttle Valve

(52).

A

SSEMBLY

Summary of Contents for ALCOA 212

Page 1: ...11 09 2009 HK838 INSTRUCTION MANUAL 212 PNEUDRAULIC INSTALLATION TOOL...

Page 2: ......

Page 4: ...This page is intentionally blank...

Page 8: ...212 Series Tooling Alcoa Fastening Systems 6 Fig 1 Outline Drawing...

Page 23: ...212 Series Tooling Alcoa Fastening Systems 21 Fig 5 Handle Assembly...

Page 25: ...212 Series Tooling Alcoa Fastening Systems 23 Fig 10 Piston and Gland Removal...

Page 26: ...212 Series Tooling Alcoa Fastening Systems 24 Fig 11 Piston and Gland Insertion assembly...

Page 27: ...212 Series Tooling Alcoa Fastening Systems 25 Fig 12 Gland Assembly...

Page 28: ...212 Series Tooling Alcoa Fastening Systems 26 Fig 13 Cylinder Assembly...