7

HS24LH

Tooling Alcoa Fastening Systems

A

DJUSTMENT OF SWITCHES

(

FOR

5/8” & 16

MM

)

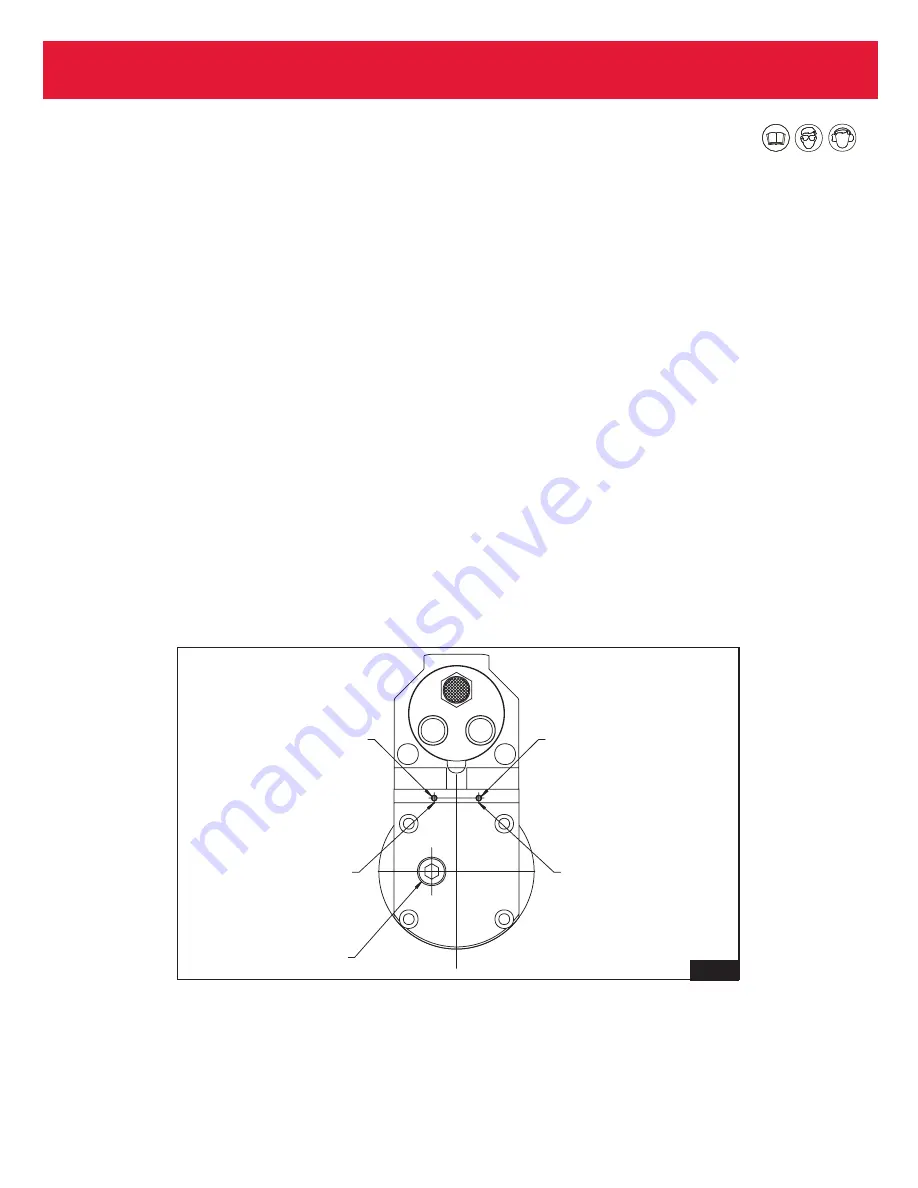

REMOVE PLUG FOR ACCESS

TO THIMBLE LOCKING PIN

LIMIT SWITCH 2 ADJUSTING SCREW

LIMIT SWITCH 2 LOCKING SCREWS

LIMIT SWITCH 1 ADJUSTING SCREW

LIMIT SWITCH 1 LOCKING SCREWS

Switches:

The HS24 tool uses two limit switches. Limit switch one

(LS-1) senses when the tool's actuator rod first touches

the fastener with approximately .275in/7mm of the

fastener engaged in the thimble. This will allow the tool to

start a "snub" cycle. Limit switch two (LS-2) senses that

there is enough of the fastener engaged by the thimble,

approximately .500in/12.7mm to completely swage the

collar.

Set Up:

To set limit switches, connect the tool to appropriate

manifold and controller. Turn on all power except for the

hydraulic powering. The "tool connected" light should be

the only light illuminated on the controller/manifold.

Setting Limit Switch One:

Screw a fastener approximately .300in/7.5mm into the

thimble. Loosen the two screws that lock limit switch one

(LS-1) in place. Slide the screws forward or rearward until

the Limit Switch One (LS-1) just illuminates. If necessary

or helpful, move the adjusting screw at the back of the

switch housing in or out until the to the appropriate setting

is obtained. Tighten the two screws that lock the limit

switch.

Setting Limit Switch Two:

Screw a fastener approximately .525in/13.3mm into the

thimble. Loosen the two screws that lock limit switch two

(LS-2) in place. Slide the screws forward or rearward until

the Limit Switch Two (LS-2) just illuminates. If necessary

or helpful, move the adjusting screw at the back of the

switch housing in or out until the to the appropriate setting

is obtained. Tighten the two screws that lock the limit

switch.

Fig. A

Summary of Contents for HS24LH

Page 1: ...Form HK 1024 04 22 2004 INSTRUCTION MANUAL HS24LH HYDRAULIC INSTALLATION TOOL ...

Page 9: ...9 HS24LH Tooling Alcoa Fastening Systems FIGURE 1 HS24LH T OOL A SSEMBLY D RAWING ...

Page 10: ...10 HS24LH Tooling Alcoa Fastening Systems FIGURE 2 126601 S WITCH A SSEMBLY D RAWING ...

Page 11: ...11 HS24LH Tooling Alcoa Fastening Systems FIGURE 3 126570 C YLINDER A SSEMBLY D RAWING ...

Page 12: ...12 HS24LH Tooling Alcoa Fastening Systems FIGURE 4 126571 P ISTON A SSEMBLY D RAWING ...

Page 13: ...13 HS24LH Tooling Alcoa Fastening Systems FIGURE 5 126572 E ND C AP A SSEMBLY D RAWING ...

Page 14: ...14 HS24LH Tooling Alcoa Fastening Systems FIGURE 6 126602 H YDRAULIC A SSEMBLY D RAWING ...

Page 15: ...15 HS24LH Tooling Alcoa Fastening Systems FIGURE 7 126603 H ANDLE W IRING A SSEMBLY D RAWING ...

Page 16: ...16 HS24LH Tooling Alcoa Fastening Systems FIGURE 8 126604 D RIVE A SSEMBLY D RAWING ...

Page 18: ...18 HS24LH Tooling Alcoa Fastening Systems SERVICE NOTES ...