25

Troubleshooting

DO NOT:

● Service the stove with wet hands. The stove is an electrical appliance, which may pose a shock hazard

if handled improperly. Only qualified technicians should deal with possible internal electrical failures.

● Remove any screws from inside the firebox without first applying a penetrating oil lubrication.

WHAT TO DO IF:

1. The stove will not start.

2. The stove will not operate when hot.

3. The exhaust blower will not function normally.

4. Light # 2 on Heat output bar flashing.

5. Auger light flashes but auger motor does not turn at all

6. The 200 °F (93 °C) high limit temperature sensor has tripped.

7. The convection blower will not function normally.

8. Ignitor- the pellets will not light.

9. Control settings (Heat Level) has no effect on the fire.

10. The stove keeps going out.

*NOTE:

All troubleshooting procedures should be carried out by qualified technicians or

installers.

1. The stove will not start.

Make sure the stove is plugged in and the wall outlet is supplying power.

If the Control Board has been placed in the ON /OFF thermostat mode, then turn the thermostat up to

call for heat.

Ensure the burn pot liner is correctly placed in the burn pot

Check the Heat Level Indicator. - If the # 2 light is flashing (see the # 2 light is flashing)

Check the fuse on the circuit board.

If the unit still does not start, contact your local service dealer for service.

2. The stove will not operate when hot.

Check the Heat Level Indicator if a fire is not detected, or if the fire has gone out

the #3 light will

flash

because the Exhaust Temperature Sensor’s contacts have opened.

Check the hopper for fuel.

Incorrect air damper setting. - Excessive air may consume the fire too quickly before the next drop of

fuel, leaving completely unburned fuel in the burn pot liner. - Insufficient air will cause build up, further

restricting the air flow through the Burn Pot Liner. This in turn will cause the fuel to burn cold and very

slowly. Fuel may build up and smother the fire. In this case clean the burn pot.

(NOTE: unit may

require a change to the vent system or installation of fresh air to correct Air to Fuel ratio

problems).

Combustion Blower failure. - The Combustion Blower is not turning fast enough to generate the proper

vacuum in the fire box. Visual Check – is the blower motor turning.

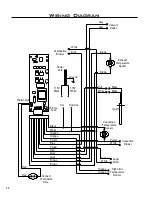

Check the Exhaust Blower voltage across the blower wires (>=114 V on #5 setting and >= 82 on #1

setting). – Replace the Circuit Board if the Voltage reading is less than 82 V. with a line voltage >115

V AC.