10

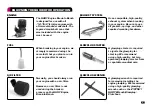

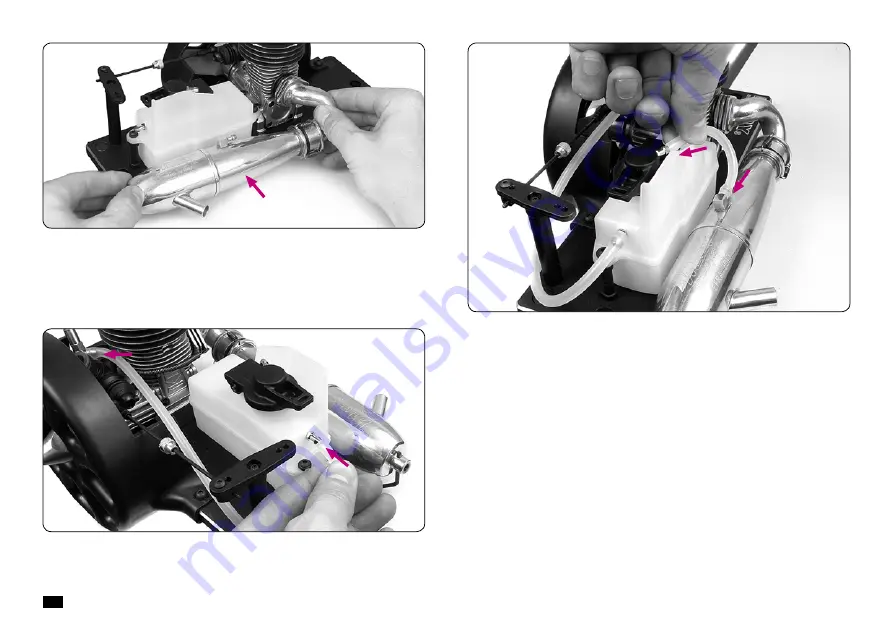

3. Attach the exhaust pipe header to the engine exhaust

outlet; remember to use the proper gasket and springs.

Attach the pipe to the exhaust mounting wire and

tighten the setscrew securely.

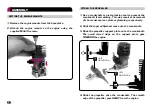

4. Use a length of silicone fuel tubing to connect the fuel

tank to the carburetor inlet.

5. Use a length of silicone fuel tubing to connect the

exhaust pipe pressure fitting to the fuel tank cap

pressure fitting.