16

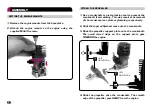

3. For the first tank of fuel, run the engine at 25%

throttle.

The engine should run very slightly rich. If not, stop the

engine by closing the throttle completely and pinching

the fuel line with needle-nose pliers… being careful

not to damage the fuel line or get the pliers near the

spinning propeller. Adjust the main needle and finish the

remainder of the first 10min break-in period.

4. Stop the engine and allow it to cool down completely.

Make sure the piston does not get stuck at TDC (top

dead center – at the top of the cylinder); rotate the

propeller by hand to move the piston to the bottom of

its stroke (BDC – bottom dead center).

5. Run the engine through several more heat cycles:

a) more tanks of fuel at 50% throttle (the engine

should still be running slightly rich), with complete

cool-downs.

b) more tank of fuel at 70% throttle (the engine should

be running crisply now), then complete cool-down.

During the final tank of fuel, vary the throttle and

check the crispness of the engine response.

EnginE tEmpERAtuRE

Throughout the break-in process, regularly check the

engine temperature to ensure it stays within the range

of 200–250°F. This is only a guideline and may vary from

engine to engine. The engine temperature and RPM should

be steady and not vary significantly; any significant changes

indicate that the carb settings require attention.