HUGH CRANE (Cleaning Equipment) Ltd –

COMMANDO

®

5050

Page 16

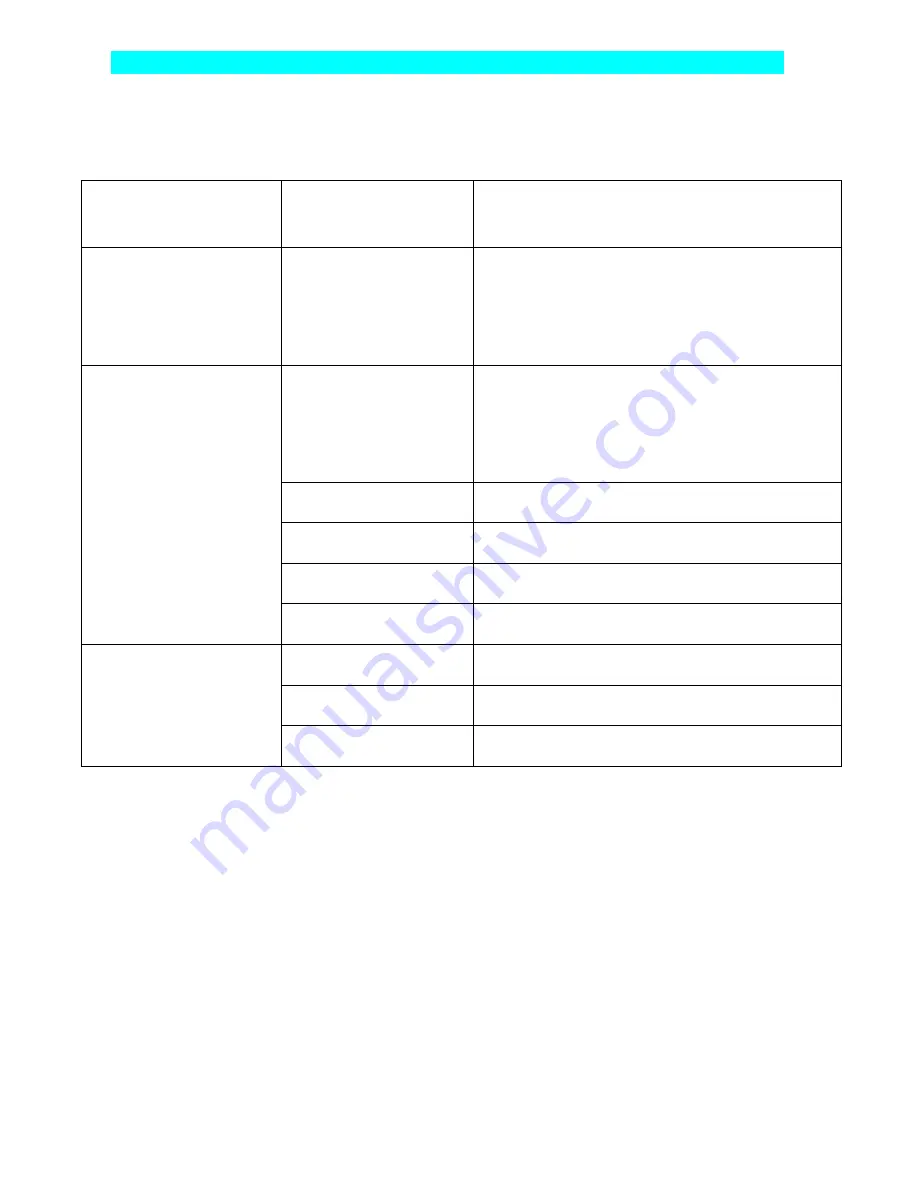

TROUBLE SHOOTING

FAULT

CAUSE

ACTION

1. Knocking noise from

pump.

Water starvation.

Pump sucking in air.

Ensure that there is sufficient water in the

tanks.

Check that the strainer is not blocked and that

the pump inlet valve is open.

Check the suction hose for leaks, which might

allow air to be drawn in.

Water starvation.

Pump sucking in air.

Ensure that there is sufficient water in the

tanks.

Check that the strainer is not blocked and that

the pump inlet valve is open.

Check the suction hose for leaks, which might

allow air to be drawn in.

Lance nozzle too large

or missing.

Check that the correct nozzle is fitted and is in

good condition.

High pressure water

leak.

Examine the high pressure hose and fittings

for leakage.

Unloader not correctly

set up.

Have unloader checked by a suitably equipped

and trained engineer.

2. Loss of pressure.

Pump speed too low.

Check that engine speed is correct.

Pump speed to high.

Stop engine immediately

. Restart at idle and

reset engine speed.

Lance nozzle too small

or blocked.

Check that the correct nozzle is fitted and is in

good condition.

3. Pressure too high.

4. Safety valve passing

water.

Unloader not correctly

set up.

Have unloader checked by a suitably equipped

and trained engineer.