11

...A: Current Unit (Ampere)

...KVA: Power Unit (KVA)

...%: Duty Cycle Unit

...A/...V~...A/...V: Output Range. Rated minimum and maximum welding current and related load

voltage.

IP21S: Case Protection Class. ‘IP’ is the code of International Protection. ‘2’ mean preventing user’s

finger from the dangerous parts; preventing the solid material with the diameter no less than 12.5mm

into the box. ‘1’ means preventing water dropping vertically which is harmless. ‘S’ means water proof test

is conducting while the movable parts are standstill.

H: H Insulating Grade.

Installation and commissioning

ATTENTION:

The protection class of INVERMIG

III

series semi-automatic gas shielded welder is IP21S.

It is forbidden to put in a finger or insert a round bar less than 12.5mm (metal bar in particular) into the

welder. No heavy force can be employed on the welder.

Warning!

The welder must be grounded before using. No disassembling earth cable if welding is not

end, otherwise, it will do harm to human body. When several welders or with other electrical appliances

are using a common grounding device, they must be parallel connection, series connection is forbidden.

The welder’s ground cable sectional area should not be less than that of input power cable.

4.1. Connection to power supply

* The welder must be loaded in the place where is less dust, no chemical, erodible, inflammable or

explosive gas and goods around the welding site.

* The welder should be installed in the place where it can not be exposed to sun and rain. Also it must be

stored in less humid place with the temperature range

﹣

10

~﹢

40

℃

mm.

* There should be at least 50cm space for the welding machine.

* Apparatus to exclude wind and smoke should be equipped if the inside aeration is not sound.

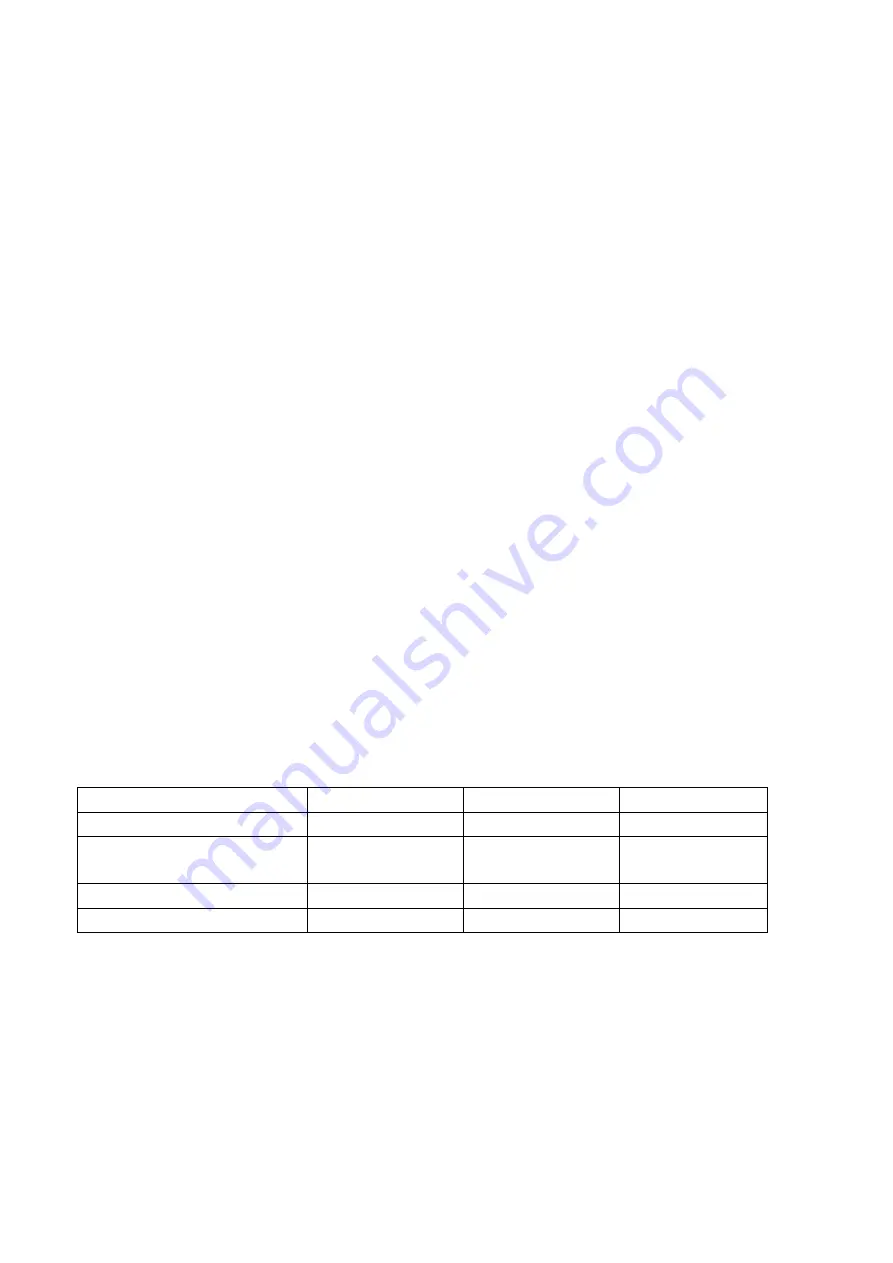

The power supply for single unit:

INVERMIG 350

III

INVERMIG 400

III

INVERMIG 500

III

Air switch (A)

≥40

≥40

≥60

Fuse (rated working current)

(A)

40

40

60

Knife switch (A)

≥40

≥40

≥60

Power cable (mm2)

≥4

≥4

≥6

Remark: the fusing current shall be 2 times to rated working current.

4.2 Installation and connection of wire feeder

* Open the spool cover and put the wire on the spool. The wire shall turn counter-clockwise. There is a

damp adjusting device in the wire spool. During rough adjustment, the wire can be pulled by hand.

Please adjust damp bolt counter-clockwise, if the resistance is too strong, and vice versa.

* Please check the wire feeder roll carefully and make sure the correct roll is used.

* Feed wire to guiding liner of wire feeder, go through roll, the insert wire in brass socket, then press

down the roll to tight.