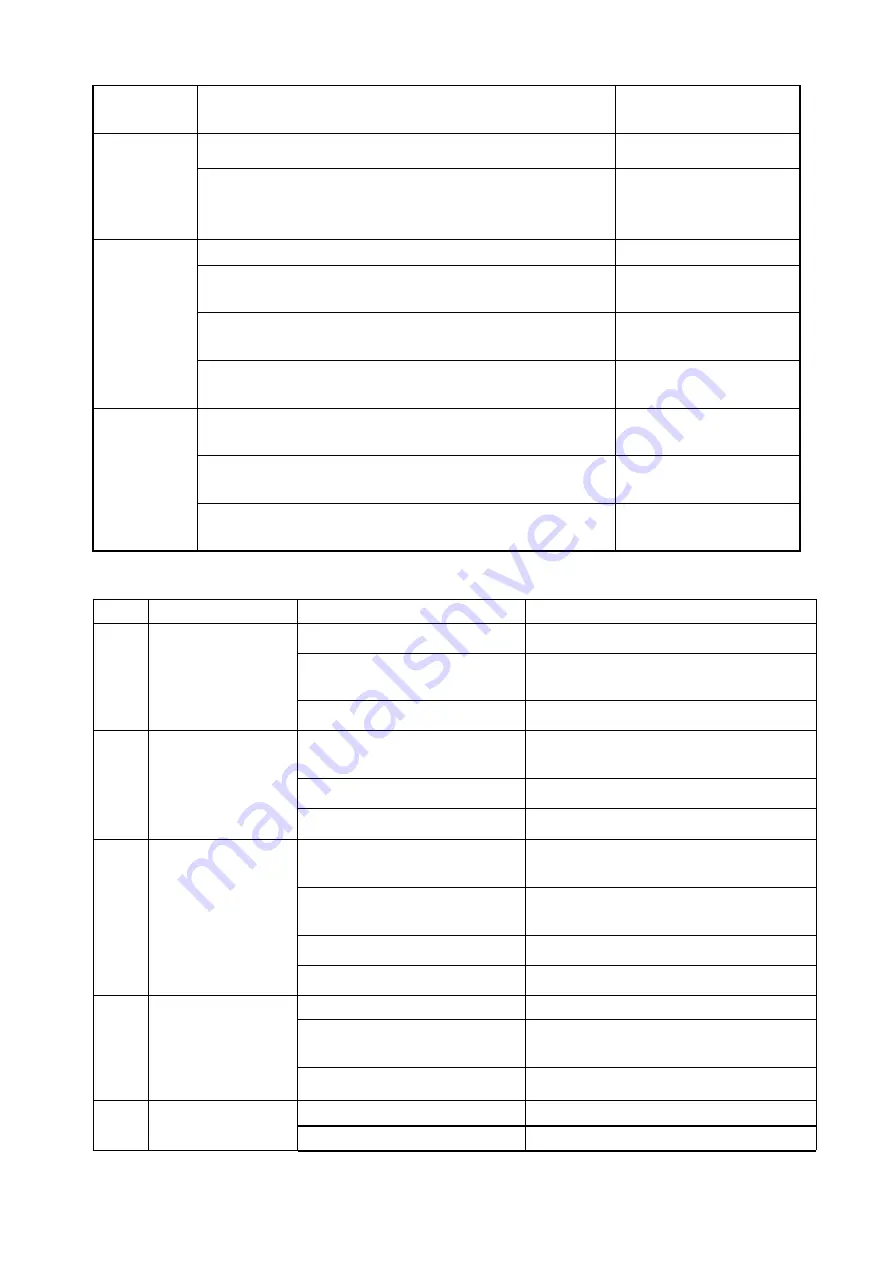

17

base plate groove is too deep

change

the

shallow

plate groove

Slag

Inclusion

the former molten slag of welding bead is not cleaned

remove molten slag

small current, too much weld slowly deposition, to much

swing during welding

increase

the

current

and reduce the swing

during welding

Big spatter

welding current and voltage doesn’t match

Adjust the welding data

There is too much oil, rust or water on wire or work-piece

clean the wire and work

piece

wire is streching too long outside the nozzle

press the torch closer to

work-piece

too big diameter of the nozzle

Change

to

suitable

nozzle

Penetration

is

not

enough

welding current is too small

Increase

welding

current

wire is streching too long outside the nozzle

press the torch closer to

work-piece

groove is not good

,

too small angle

,

too small gap

change

the

welding

technology process

* Common Failure of welding machines and solution

No.

Failure

Failure reason

Solution

F1

Fan is not turing

Fan is broken

Change the fan

Loose connection

Check where is the loss connection

and tighten it

other

Contact the seller

F2

Protection LED is

on

overheat

of

the

internal

machine

Wait till the temperature is coming

down and light is off

Thermal relay is broken

Change thermal relay

other

Contact the seller

F3

Current

and

voltage no display

Current and voltage display is

broken

Change the display

Loose connection

Check where is the loss connection

and tighten it

Main control board is broken

Change the main control board

Other

Contact the seller

F4

When press the

torch button, the

torch is not on

Torch switch is broken

Change the torch switch

Cable

connection

is

not

connected

Contact the cable

Control board is broken

Change or repair the control board

F5

No gas

Gas hose is blocked

Connect the gas

Gas hose is press

Check the gas flow