3

ENGLISH

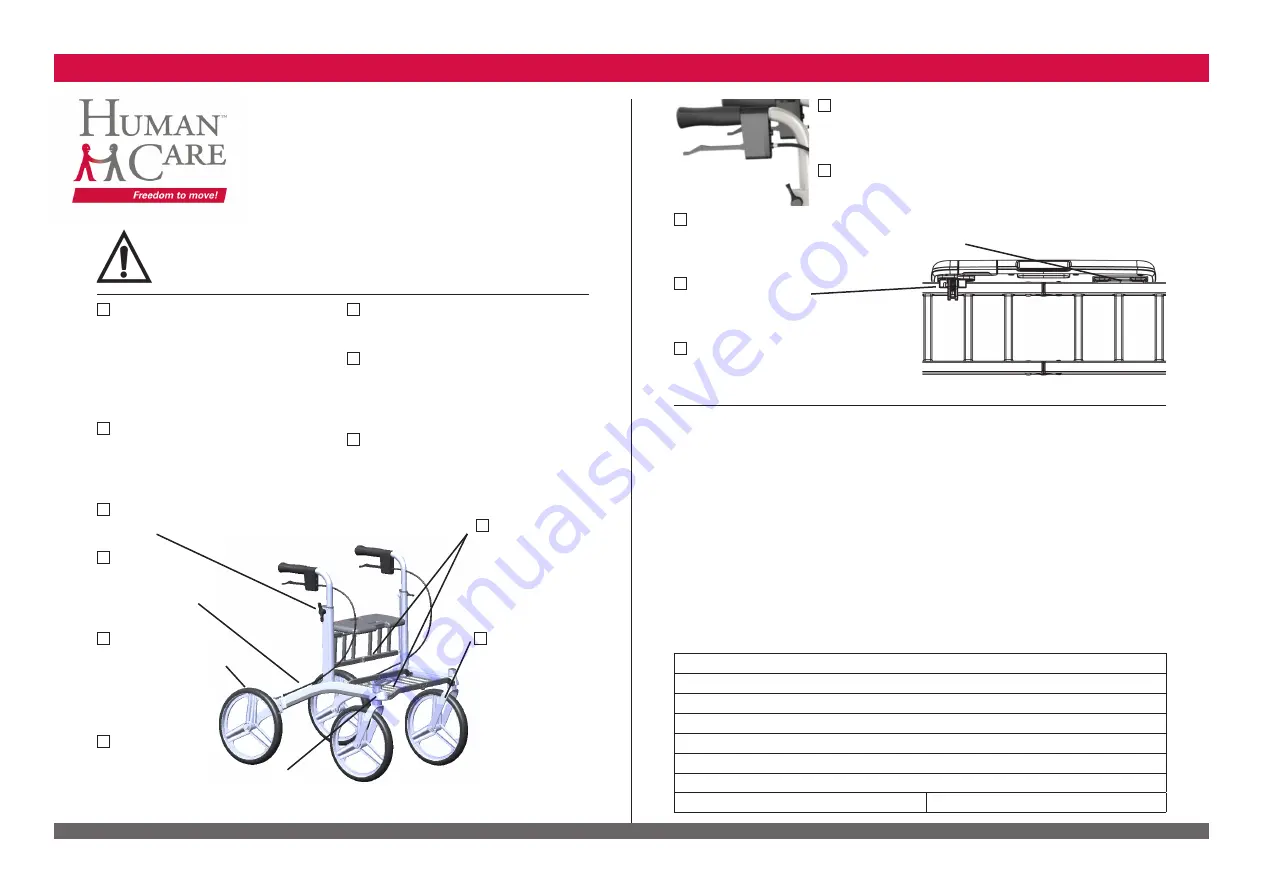

Carla

To secure that the walking-aid will function safely for the user,

once per year review of the walking-aid should be done.

Cleaning

Painted areas, wheels and handles should

be cleaned with a regular cleansing solution,

without solvent.

Note!

Do NOT use thinner, petrol or

other solvents.

Post treatment

After washing, all connections, tight spaces

and drainage holes should be blown dry and

if needed sprayed with thin oil.

Wing nut

Control.

CE-marking

Make sure that the CE-

mark is still there and

readable.

Wheel

Make sure the wheels are

not worn-out and are

spinning easily

(without any noice).

Reflectors

Make sure the

reflectors are still there and visible.

Handle

Must be fixed. Make sure the handle pipes can be pushed down

to the chassis.

Brakes

Control that both brakes and parking brakes are working.

Wires shall be intact.

Seat

Make sure the seat is kept in place and the screws are tightened. For more

details, see back page.

Folding mechanism

Should be intact and the locking device

should function.

Test driving

Make a final control by test driving.

For more details, see back page.

Note!

Recondition must be done by a person how has good knowledge about how the job

should be performed. An incorrect performed recondition could result an accident/

incident. Don´t hesitate to contact your retailer if questions come up.

When exchanging parts of the rollator, use only Human Care parts to ensure continued

CE-validation.

When changing the wheel locking liquid shall be applied on the nut and screw.

If the corrosion is more than a film of rust the rollator shall be discarded and return for

recycling.

Intended use

The rollator should only be used as support whilst walking or as seating whilst stationary.

Do not alter the rollator yourself.

Product number:

Owner:

Notes:

Attended by:

Date:

The Paint

Control the paint for possible damages.

Stability

Control that all wheels are steadily on

the ground and that there are no chassis

distortion.

Chassi

Control weldings and screw attaches.

By larger corrosion the rollator shall be

changed.

Lubrication

Gatebushings and

hinges should be

working without

any noice. Lubricate

when needed.

Front forks

Make sure that the

ball bearing is firmly

attached and that

the forks swings

easily.

Note!

The nut on

the fork must not be

touched.