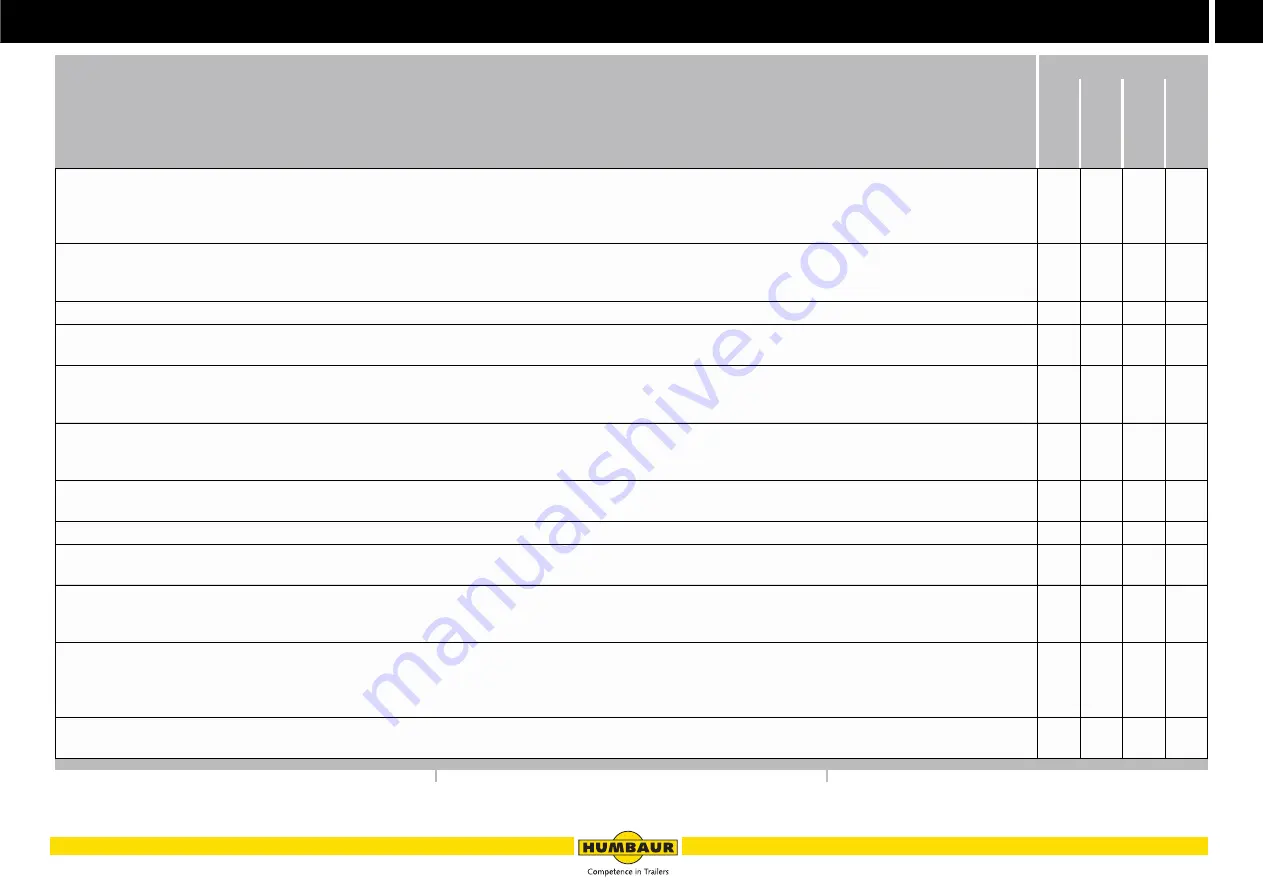

Maintenance intervals

149

Testing, care and maintenance

7

Tab. 3

Maintenance table: Regular intervals

Supports:

Check jockey wheel, support legs are working and are stable.

- Lubricate jockey wheel at grease nipple and moveable parts

- Check screw connections are tight

- Have worn tyre on jockey wheel / deformed jockey wheel replaced

X

Wheel shock absorber:

Check for oil leakage and for firm fit

- Replace faulty wheel shock absorbers in pairs

- Check attachment points / screw connection for firm fit and tighten if required

X

Gas struts:

check whether present, that they are working and tightly fitted

X

- Check gas struts for deformation of piston rod and replace if necessary

- Check gas struts on ramp doors / cover for slackening and if necessary replace in pairs

X

Hydraulic system:

Check function / tightness

- Check oil level and top up if necessary

- Check that pump lever is present and not damaged, order a new one if necessary

X

- Check hydraulic hoses for cracks, aging, breakage, stone dents and replace if necessary

- Clean connection / bearing points for telescopic cylinder and lubricate

- Check electric-hydraulic system (remote control) for damage, ensure it is working

X

Battery:

Check for external damage / acid leaking out

- Recharge a weak battery.

X

- Check charging state, recharge ability and replace faulty / old battery

X

Manufacturer signs / warning labels:

Check they are present and legible

- Reorder damaged / illegible signs, labels and replace

X

Cargo bed / lashing points:

Check surface of cargo bed for damage (rust, oxidation) and have repaired if necessary

- Check that lashing points are present, check for damage and replace if necessary

- treat wooden surface with preservative as required: linseed oil / turpentine

X

Added structures / bodies

(rail, side wall extension, H-frame, cover, roofbow frame, cover, toolbox etc.):

- Check fasteners, locks, hinges work and grease as required

- Check tarpaulin for tears and have repaired if necessary

- Check screw / riveted connections for firm fit and tighten if required

X

Cable winch:

Clean bearing points (bearing bushing, drum hub, sprocket, pulley) and grease / lubricate

- Unroll wire cable and check for cracks, wear (pinching, individual broken wires) and replace if necessary

X

Regular inspection / maintenance work

after

500 km

(1 month)

2000 km

(3 months)

5000 km

(6 months)

10000 km

(12 months)

Summary of Contents for 1000 Series

Page 1: ...GENERAL CAR Program PART 1 OPERATING MANUAL humbaur com 1000 8400 SERIES EN ...

Page 9: ...1 7 Safety ...

Page 21: ...2 19 General information ...

Page 31: ...3 29 Operation ...

Page 67: ...3 65 Operation Trailer safety ...

Page 75: ...4 73 Chassis ...

Page 103: ...5 101 Body ...

Page 134: ...Cover net 5 132 Body ...

Page 135: ...6 133 Electrical system ...

Page 145: ...7 143 Testing care and maintenance ...

Page 185: ...8 183 Troubleshooting guide ...

Page 194: ...Hydraulics 8 192 Troubleshooting guide ...

Page 195: ...9 193 Proof of inspection ...