7

Lubrication

160

Testing, care and maintenance

Information on implementation

To lubricate / grease the components, only used the listed

lubricants.

Type of lubricant:

–

Multipurpose grease according to

ISO-L-XCCHB3

or

–

according to

DIN 51825 - Type K

with application range:

-30 °C to + 120 °C

–

Oil: commercially available machine oil

The intervals for lubrication are to be adapted

according to the intensity of use and degree of

contamination.

WARNING

System failure due to incorrect lubrication

There are some component which must not be lubricated /

greased under any circumstances. The components could

then fail to work - risk of accident!

Find out which components must not be lubricated, for

example:

Friction linings of ASK safety coupling, clamping tube on

prop stand, thread on wheel bolt, brake pads, etc.

CAUTION

Contact with lubricant

Lubricants can cause reactions with your skin.

Only use approved lubricants.

Carefully clean the grease nipple before lubricating.

Use , .

after working with lubricants.

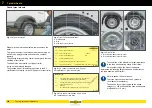

Before lubricating

Fig. 40

Prepare grease nipple

1

Cap

NOTICE

Dirty grease nipple

Dirt could get into the bearing and cause higher wear.

Grease nipple and grease gun could be damaged.

Clean grease nipples before lubricating.

Dirt can prevent the components from working!

Remove all of the old grease / old oil from the lubrication

point.

Remove any foreign objects such as blades of grass,

leaves or small twigs that have caught in the bearings or

the spaces in between.

If necessary, remove the cap (Fig. 40 /1) from the grease

nipples.

Clean the lubrication points / grease nipples with a clean,

dry fabric cloth.

After lubricating

Fig. 41

Lubricating

1

Grease nipple cleaned

Wipe of any dripping / excess grease with a fabric cloth.

If required, close the grease nipple (Fig. 41 /1) with a

cap.

Check that the components are working properly.

W - 051

1

W - 052

1

Summary of Contents for 1000 Series

Page 1: ...GENERAL CAR Program PART 1 OPERATING MANUAL humbaur com 1000 8400 SERIES EN ...

Page 9: ...1 7 Safety ...

Page 21: ...2 19 General information ...

Page 31: ...3 29 Operation ...

Page 67: ...3 65 Operation Trailer safety ...

Page 75: ...4 73 Chassis ...

Page 103: ...5 101 Body ...

Page 134: ...Cover net 5 132 Body ...

Page 135: ...6 133 Electrical system ...

Page 145: ...7 143 Testing care and maintenance ...

Page 185: ...8 183 Troubleshooting guide ...

Page 194: ...Hydraulics 8 192 Troubleshooting guide ...

Page 195: ...9 193 Proof of inspection ...