Lubrication

161

Testing, care and maintenance

7

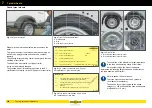

Ball coupling

Fig. 42

Ball coupling: Bottom view

1

Safety indicator / mechanics

2

Spherical cap

3

Coupling cup

4

Spring mechanism

Clean the ball head coupling on the inside as well.

Check the spherical cap (Fig. 42 /2) and the coupling

shell (Fig. 42 /3) for wear.

If the ball head coupling shows significant signs of wear

or the spring mechanism (Fig. 42 /4) is malfunctioning,

have it replaced.

Apply multi-purpose grease onto the spherical cap /

coupling shell from below.

Fig. 43

braked: Top view

Fig. 44

unbraked: Side view

1

Oiling points

2

Lubrication / sliding points

Drip some standard machine oil onto the bearings and

joint areas (Fig. 43 /1 and Fig. 44 /1).

Grease the lubrication / sliding points (Fig. 43 /2 and

(Fig. 44 /2).

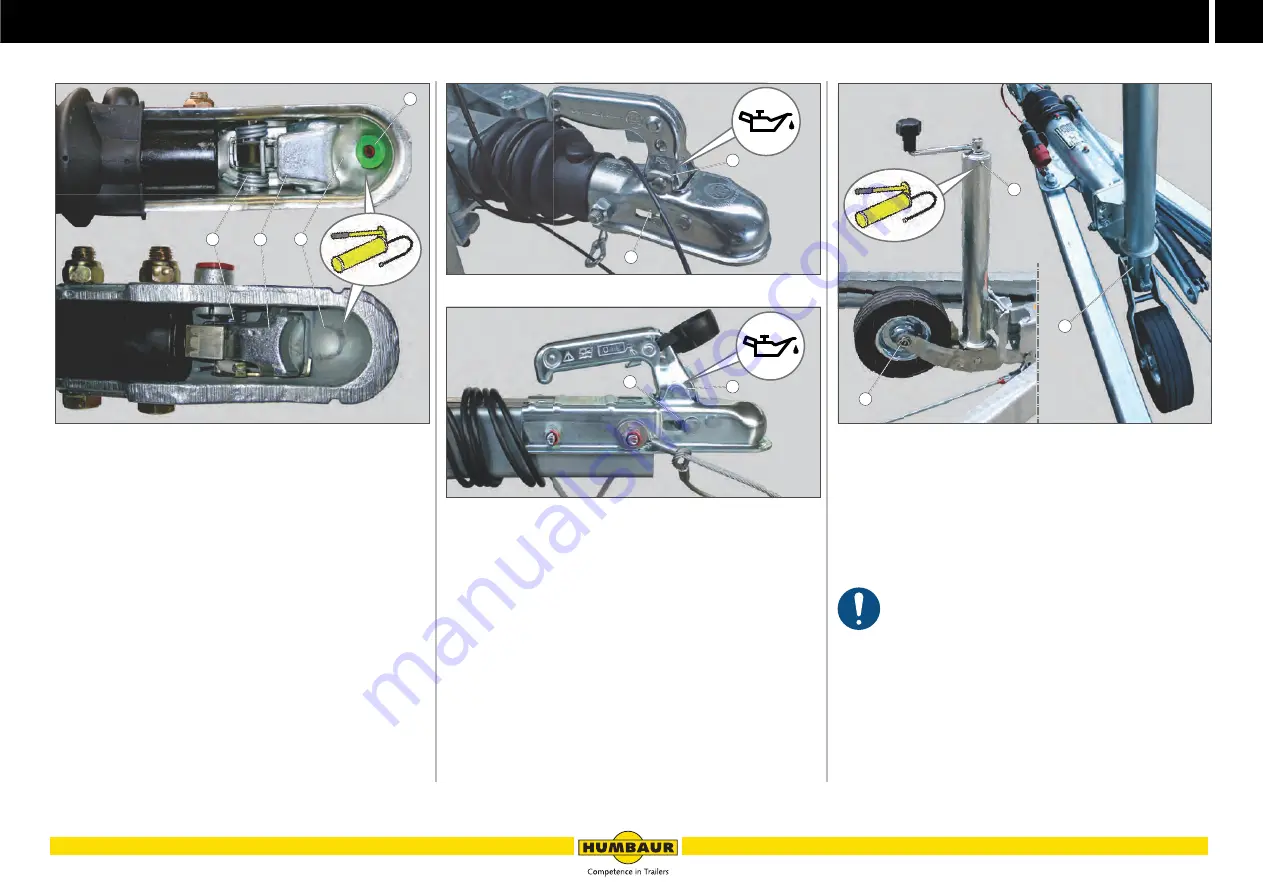

Automatic jockey wheel

Fig. 45

Automatic jockey wheels: Lubrication points

1

Grease nipple

2

Sliding point

3

Bearing point / wheel

Lubrication of the jockey wheel should be carried

out while the trailer is coupled to a vehicle.

Check the bearing point and the wheel (Fig. 45 /3) for

deformation.

Lubricate the jockey wheel at the grease nipple

(Fig. 45 /1) using a grease gun.

Grease the sliding point (Fig. 45 /2).

Crank the jockey wheel up and down several times - the

grease will distribute itself.

W - 053

1

2

3

4

W - 054

1

2

W - 055

1

2

W - 056

1

2

3

Summary of Contents for 1000 Series

Page 1: ...GENERAL CAR Program PART 1 OPERATING MANUAL humbaur com 1000 8400 SERIES EN ...

Page 9: ...1 7 Safety ...

Page 21: ...2 19 General information ...

Page 31: ...3 29 Operation ...

Page 67: ...3 65 Operation Trailer safety ...

Page 75: ...4 73 Chassis ...

Page 103: ...5 101 Body ...

Page 134: ...Cover net 5 132 Body ...

Page 135: ...6 133 Electrical system ...

Page 145: ...7 143 Testing care and maintenance ...

Page 185: ...8 183 Troubleshooting guide ...

Page 194: ...Hydraulics 8 192 Troubleshooting guide ...

Page 195: ...9 193 Proof of inspection ...