Load securing

3

50

Operation

Tie-down points in / on the cargo bed

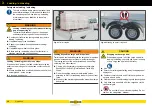

Fig. 55

Example: Tie-down force information

1

Sticker

2

Front drop side

Check that the number of tie-down points and the max.

tie-down forces are sufficient for the goods to be tied

down.

If applicable, fit more lashing points.

Replace any damaged / worn tie-down points.

Tie-down points

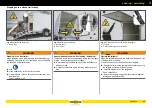

Fig. 56

Tie-down brackets which can be recessed

Tie-down force = max. 400 daN (kg)

1

Tie-down bracket

2

Drop wall profile

3

Cargo bed (floor plate)

Fig. 57

Tie-down brackets which can be recessed

Tie-down force = max. 800 daN (kg)

1

Tie-down bracket

2

V lashing rail

3

Cargo bed (floor plate)

Fig. 58

Recessed tie-down points (optional)

Version 1: Tie-down force = max. 200 daN (kg)

Version 2: Tie-down force = max. 400 daN (kg)

1

Tie-ring

2

Trough recess

3

Cargo bed (floor plate)

Fig. 59

On-surface tie-down points (optional)

Tie-down force = max. 200 daN (kg)

1

Tie-ring,

screwed onto the cargo bed

B - 072

DIN Zurrpunkte

400

daN

(kg)

min. 30 °

620.00031_B

2

1

B - 073

1

2

3

B - 074

1

2

3

B - 075

1

2

3

B - 076

1

Summary of Contents for 1000 Series

Page 1: ...GENERAL CAR Program PART 1 OPERATING MANUAL humbaur com 1000 8400 SERIES EN ...

Page 9: ...1 7 Safety ...

Page 21: ...2 19 General information ...

Page 31: ...3 29 Operation ...

Page 67: ...3 65 Operation Trailer safety ...

Page 75: ...4 73 Chassis ...

Page 103: ...5 101 Body ...

Page 134: ...Cover net 5 132 Body ...

Page 135: ...6 133 Electrical system ...

Page 145: ...7 143 Testing care and maintenance ...

Page 185: ...8 183 Troubleshooting guide ...

Page 194: ...Hydraulics 8 192 Troubleshooting guide ...

Page 195: ...9 193 Proof of inspection ...