40/56

V 03/2018

Original

Operati ng Instructi on Manual

10.2 Cleaning with a high-pressure cleaner

NOTICE

Cleaning with a high-pressure cleaner!

Components and surfaces may become damaged or destroyed if

they are blasted directly with water that is too hot, the jet pres-

sure is too high or the jet is positi oned too close.

►

Read the operati ng instructi on manual that

accompanies the high-pressure cleaner.

►

Use

,

,

.

►

Keep the water jet moving in a circular moti on – do not

hold it in one positi on.

►

Take extra care when cleaning with a high-pressure

cleaner and follow the instructi ons.

of Parti cipati on

Distance from surface

min. 70 cm

Water pressure

max. 50 bar

Water temperature

max. 80 °C

►

Do not direct the high pressure cleaner towards:

•

Parts of the electric system (lighti ng system, plugs, cables)

•

Tyres

•

Wheel shock absorbers

•

Coupling head

•

Signage (identi fi cati on plate, sti ckers)

•

Hoses

•

Seals (sealed joints)

Do not clean a new trailer with a high-pressure cleaner

within the fi rst three months of use.

The surfaces / materials are sti ll sensiti ve and must

be allowed to harden completely, while galvanised

components must build up an oxide layer fi rst.

Oiled or lubricated components must be oiled, lubricat-

ed and greased again aft er intensive cleaning.

•

Lubricant: Multi -purpose grease according to ISO-L-XCCHB3

or DIN 51825 type K (applicati on range -30° to +120°).

•

Oil: commercially available universal machine oil

►

Check that the lubricati on / oiling points are greased /

oiled suffi ciently before and aft er cleaning work.

►

Lubricate / oil the relevant components / points listed in

the maintenance secti on unti l the lubricant escapes.

►

Remove any excess oil / grease that escapes using a dry

cloth.

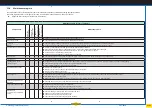

10.3 Trailer materials

1

2

3

4

5

6

Material overview (front)

H - 99

7

8

Material overview (rear)

1.

Steel, galvanised

2.

Plasti c

3.

Aluminium, anodised

4.

Soft rubber (tyres)

5. Fabric tension cables (cords)

6. PVC / syntheti c fabric

7. Multi layer wood

8.

Rigid plasti c