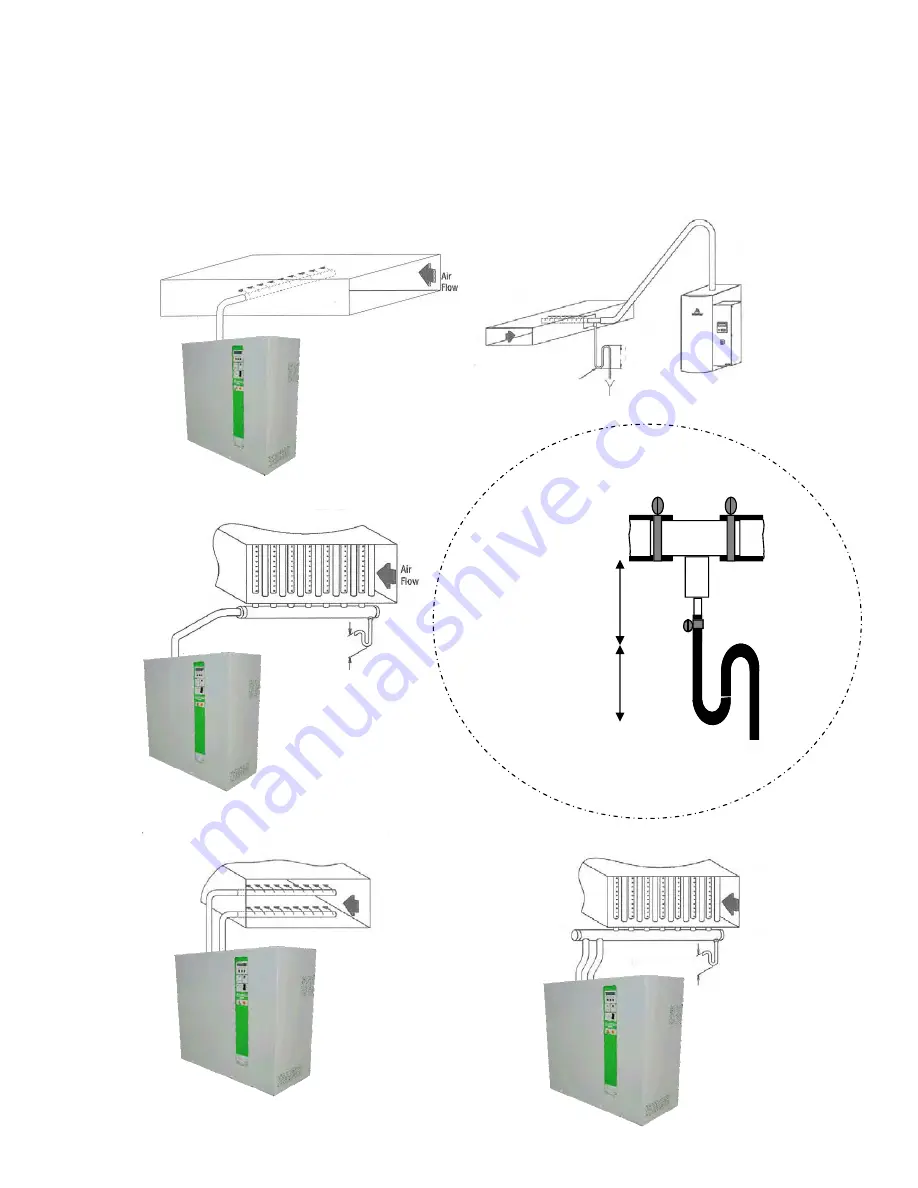

ElectroVap RTH

Steam Pipe Positioning

Installation

Pipe under humififer RTH 5 to 50

Condensate

Pipe above humidifier RTH 5 to 50

Condensate

Air

Flow

Condensate

Air

Flow

HumidiPack ® insertion in duct RTH 60 to 100

Insertion in duct RTH 60 to 100

12 in. min.

8 in. min.

Trap must be full of water before starting the unit

Condensate

Draining

HmidiPack

®

insertion in duct RTH 5 to 50

11