14

#

mm

Titan 79

b1

677x1553/1991

4

b2

609x2002/2200/2002

1

b3

609x4/204/4

1

b4

572x915

2

b5

677x1528

8

b6

677x1200

6

b7

677x612

2

b8

677x570

2

1

2

3

4

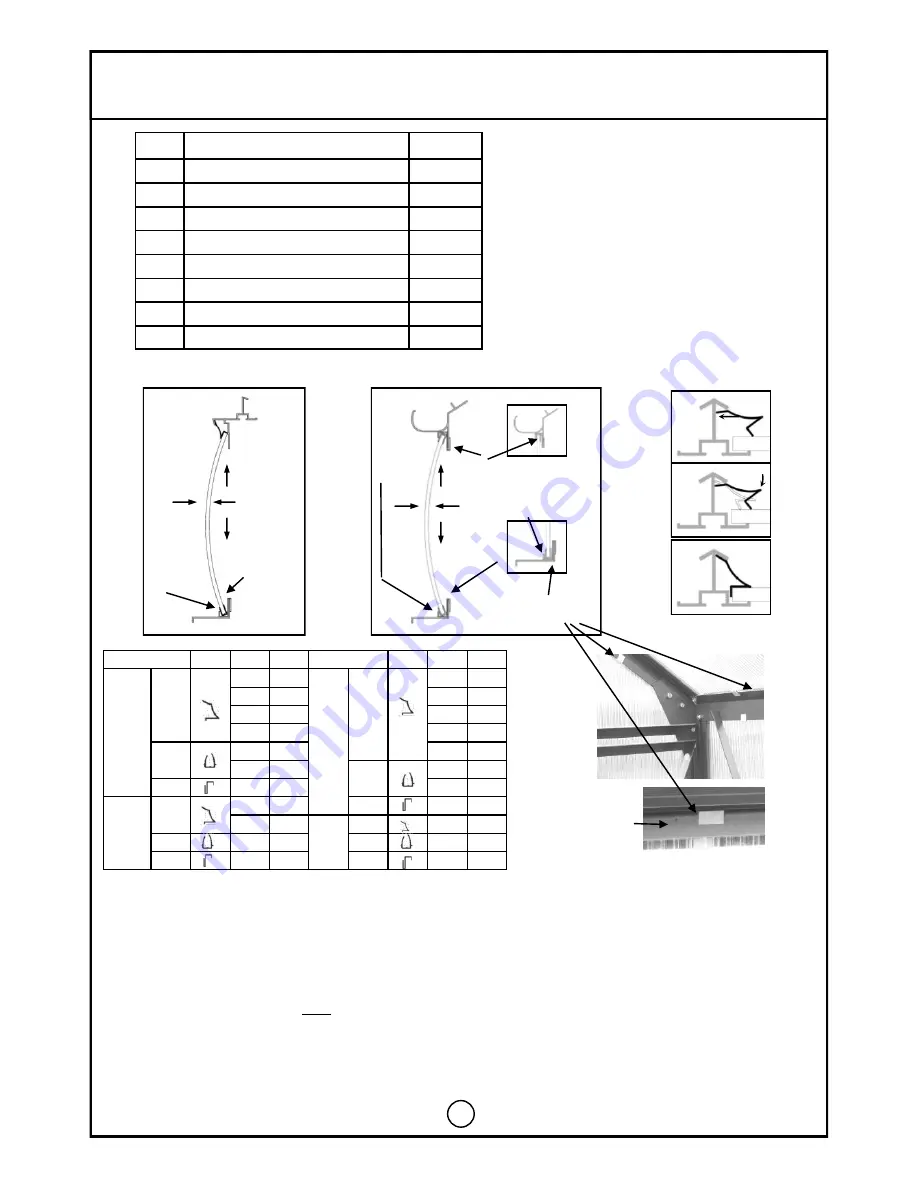

Panel

Panel

Panel

Assemble b5 Panel

3.BOTTOM

2

1. TOP

4

Assemble b1&b2 Panel

5.SIDE

DWG

Length

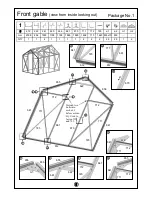

Titan 79

DWG

Length

Titan 79

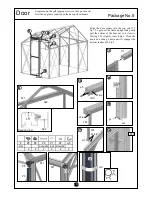

Front Gable

c

1534

2

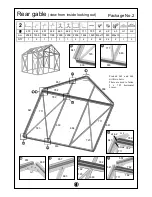

Rear

Gable

c

1534

2

1994

2

1994

2

363

2

2002

2

807

2

363

2

s

585

1

807

2

660

2

s

592

1

f

12

9

660

2

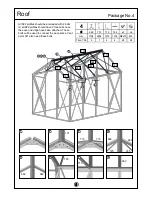

Roof

c

565

4

f

12

9

1197

12

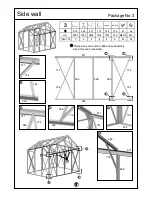

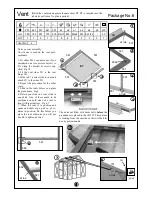

Side

wall

c

1534

16

s

660

14

s

660

16

f

12

24

f

12

48

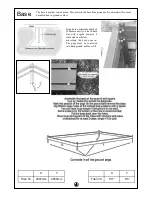

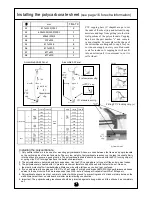

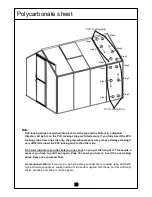

Installing the polycarbonate sheet

(see page 16 for extra information)

Installing the polycarbonate.

1. Only neutral silicone is to be used for mounting polycarbonate. Silicone is used between the frame and polycarbonate

on the vertical parts of the roof and walls. The very low weight of polycarbonate requires you to press the sheets firmly

into the silicone to ensure a good glue line. The polycarbonate sheets should be secured with the PVC locking strips (c)

or spring clips. PVC locking strips have the better wind resistance.

2. The polycarbonate is delivered with both ends open. Use the PVC capping bars (s) to seal off the ends in most cases.

3. The polycarbonate is treated with UV protection and must therefore be positioned with the text side out. Remove

the plastic protective film from both

sides. Mark one side with a felt pen so you don’t get confused.

4. If you need more silicone glue use SIKA “Fix it Fast” sealer. For high wind areas ADOS MS High performance adhesive

sealant is the best choice. A bit more expensive than SIKA, but a lot stronger. Available from Mitre 10 Mega etc.

5. Polycarbonate sheets must not come into contact with the ground to prevent ingress of dirt and moisture between the

walls. Always rest them on cardboard or similar material during construction.

6. Important: The polycarbonate greenhouse should be protected against strong winds until the silicone has completely

set.

(s)

PVC

cap

Fitting PVC locking strip (c)

(f ) aluminium clip

(s) PVC cap

(f )

Aluminium

clip

(s)

PVC

cap

(f) from outside

(f ) aluminium clip

(s)

PVC

cap

PVC capping bars (U shaped) are put over

the ends of the sheet (top and bottom) to stop

moisture and bugs from getting into the twin

wall portions of the polycarbonate. Capping

bars have the part number “s” and come in

various lengths. In some places the shape of

the extrusions are designed to cap it for you,

so it does not apply in every case. Doors and

vents for instance. A capping bar will not fit

into an extrusion if it is not meant to, so it is

self evident.