9

JINTDI05 Rev E 20/04/54

PRE-INSTALLATION REQUIREMENTS

P

LEASE CHECK THE FOLLOWING

:

Any existing chimney/flue system must be

confirmed as suitable for this appliance as defined

in Building Regulations Document J.

It must be swept and inspected, by a competent

person (see notes), to confirm that is structurally

sound and free from cracks and obstructions.

The diameter of the Flue should not be less than

Ø125mm and not more than Ø230mm. Do not

connect to systems that have large voids or

spaces. If any of these requirements are not met,

the chimney should be lined by a suitable method.

If the chimney is suspected of previously serving

an open fire it must be swept again, within a

month of regular use, to clear any soot that may

have been dislodged due to the variation in

combustion levels and higher flue gas

temperature levels.

The chimney/flue system exit must comply with

Building Regulations Document J

The minimum height of the chimney/flue system

must be 4.5 metres and should terminate in

accordance with table 1.

Make provision to access the chimney/flue system

for cleaning and the removal of debris.

If there is no existing chimney then either a

prefabricated block chimney in accordance with

Building Regulations Approved Document J, or a

twin-walled insulated stainless steel flue to BS4543

can be used. These chimneys must be fitted in

accordance with the manufacturer’s instructions

and Building Regulations. New masonry and flue

block chimneys must meet the requirements of

Building Regulations Document J. Any connecting

flue pipe systems must also meet these

regulations.

Please check the suitability of the fireplace and/or

surround for use with this appliance before

installing it. Many Fire Surrounds are only suitable

for use with gas and electric fires and therefore

may not suitable for this Solid Fuel Appliance.

Please check you Fire Surround.

Fire Surround Back Panels suitable for solid fuel

are usually in three sections and slabbed.

If you have any doubts about the suitability

of your chimney, consult your local

Dealer/Stockist

.

Both the chimney and flue pipe must be

accessible for cleaning and if ANY part of the

chimney cannot be reached through the

stove (with baffle removed), a soot door

must be fitted in a suitable position.

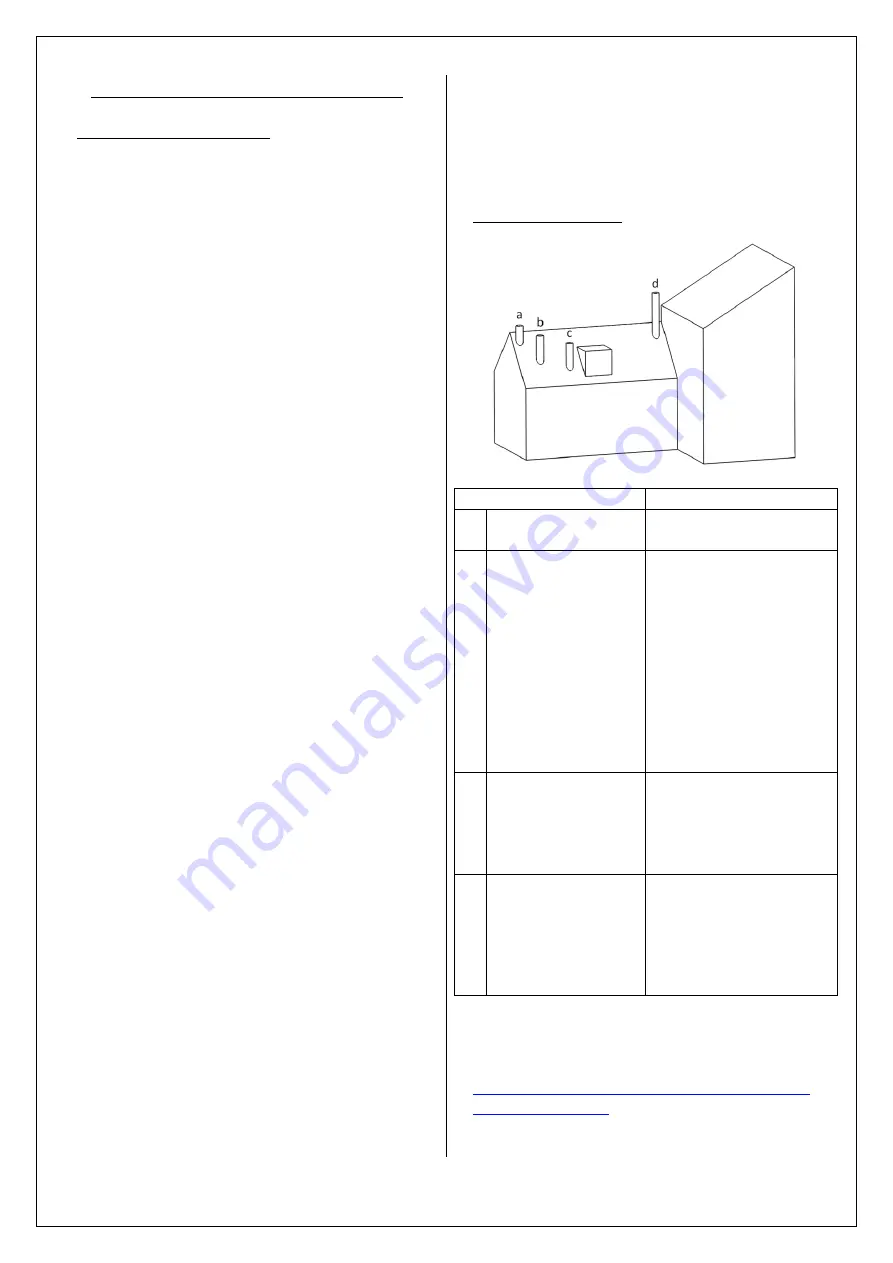

F

LUE OUTLET

P

OSITIONS

Position on Roof

Clearances to flue exit

A

At or within

600mm of the ridge

At least 600mm

above the ridge

B

Elsewhere on a roof

(Pitched or Flat)

At least 2.3 M

horizontally from the

nearest point on the

weather surface and:

a) At least 1.0 M above

the highest point of

intersection between the

chimney and weather

surface; or

b)at least as high as the

ridge

C

Below (on a pitched

roof) or within 2.3 M

horizontally to an

opening window or

dormer

At least 1.0 M above the

top of the opening

D

Within 2.3 M of an

adjoining or

adjacent building,

whether or not

beyond the

boundary

At least 600mm above

any part of the adjacent

building within 2.3 M

Table1.

– Flue Terminal Positions

A full copy of Document J can be found here:

http://www.planningportal.gov.uk/uploads/br/BR

_PDF_ADJ_2010.pdf