1 of 56

Form 6423-T, 07-12

Supersedes Form 6423-T, 05-12d

INSTALLATION INSTRUCTIONS FOR

ROAd FORCe TOUCh

®

/ GSP9700 SeRIeS BALANCeRS

Installation of a Road Force Touch

®

/ GSP9700 Series Balancer should be completed

only by an authorized Hunter Service Representative.

This document provides the information needed to install a Road Force Touch® / GSP9700 Series Balancer.

PLACemeNT

The balancer should be placed in a dry area that is not subject to moisture. Clearance for the operator at the front

and to the right of the balancer should be at least 3 feet (0.91 meter). There must also be ample clearance at the

rear of the balancer to allow the safety hood to open fully. The electrical power cord should be positioned so that

it cannot be walked on, driven over, or tripped over.

FLOOR ReqUIRemeNTS

The balancer should be placed on a

solid

concrete floor. Any floor condition, which might allow the balancer to

move during operation, is unacceptable.

If the location selected is a hard surface floor that is hollow underneath, place the balancer over a supporting

beam or close to a supporting wall.

POweR ReqUIRemeNTS

The customer must furnish a 10% / -15%, 10 amp 50/60 Hz single-phase electrical supply for the

balancer. This machine must be connected to a 20 Amp branch circuit. Please refer all power source issues to a

certified electrician.

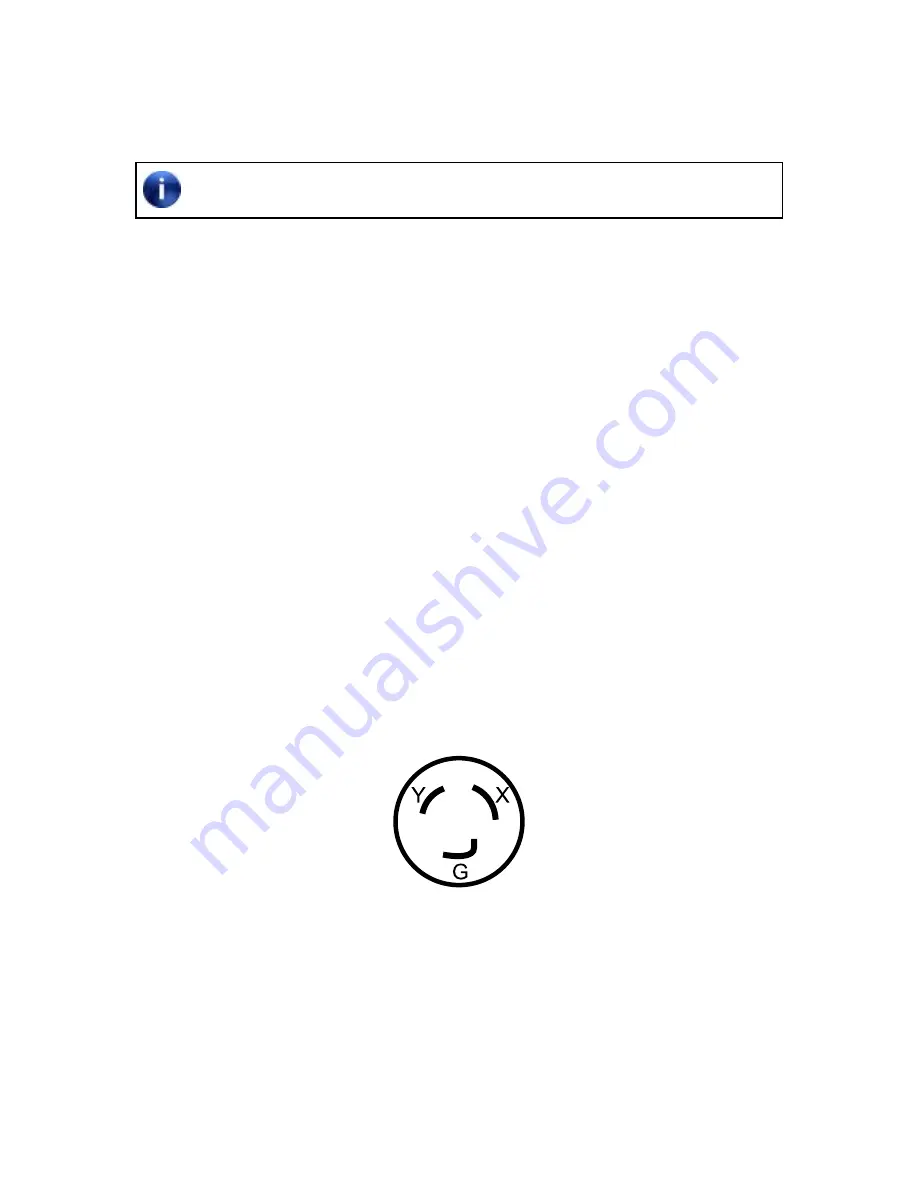

The power cord supplied utilizes a twist lock connector, NEMA L6-20P. The power cord may need modified to

match the available electrical receptacle for your region. For instructions to replace the single-phase power plug

with a three-phase NEMA L15-20P power plug refer to form 5350T. Changes to the electrical power cord, plug,

and/or power source must be performed by a certified electrician in accordance with local electrical codes.

Figure 1

PNeUmATIC ReqUIRemeNTS

The customer must provide a low-pressure air supply (between 100-175 psi (6.9–12.0 bar)). Necessary for

balancers equipped with the Auto-Clamp and Inflation Station. A moisture trap and/or filter is necessary to

provide clean, dry air.