26

3.

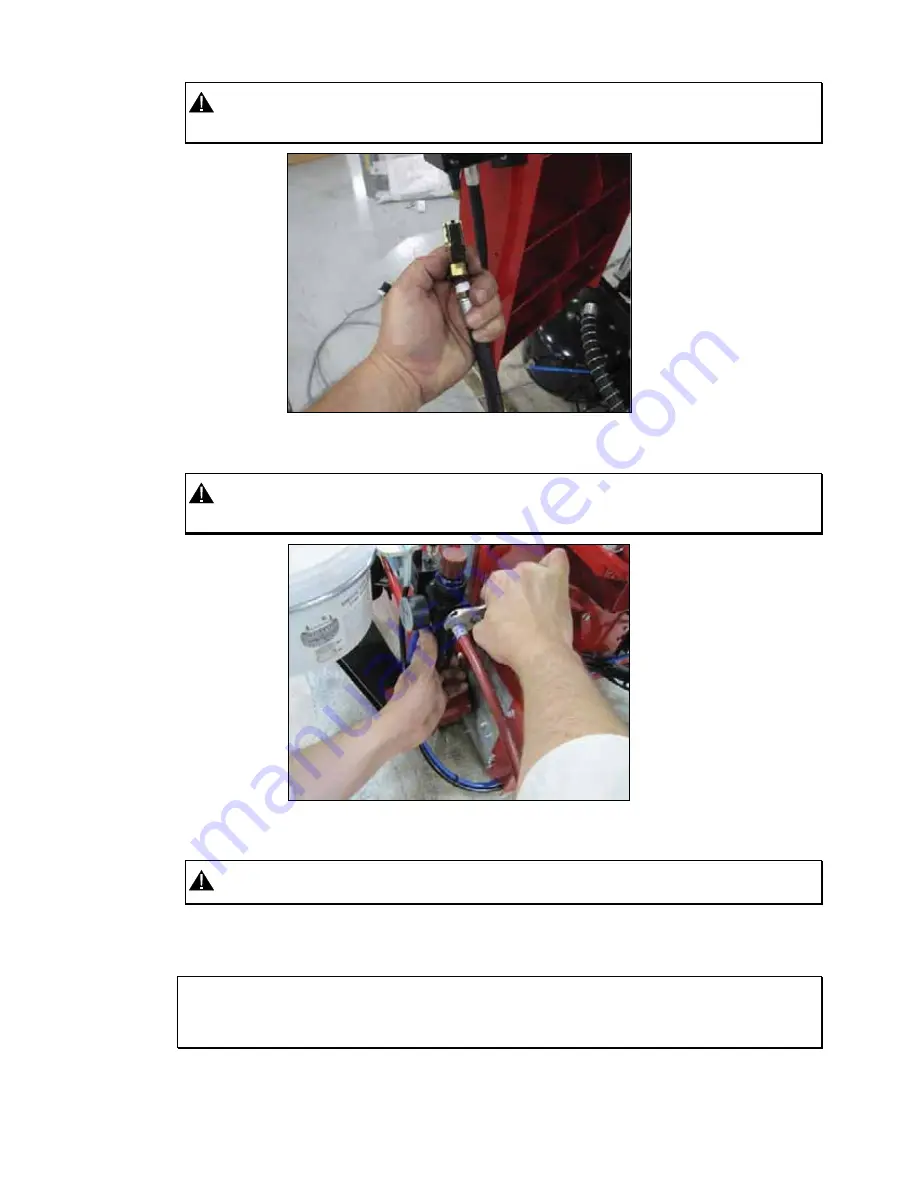

Connect air chuck to inflator hose

(Fig. 79)

.

CAUTION:

Excessive amounts of Teflon thread sealant can cause pneumatic blockage.

Use Teflon thread sealant sparingly.

Fig. 79

4.

Connect main air supply to regulator

(Fig. 80)

.

CAUTION:

Excessive amounts of Teflon thread sealant can cause pneumatic blockage.

Use Teflon thread sealant sparingly.

Fig. 80

5.

Apply air pressure to the tire changer.

CAUTION:

Supplied air pressure must not be greater than 220 psi.

6.

Verify regulated operating pressure is between 110 and 145 psi.

7.

Verify all controls operate properly.

NOTE:

The first time each pneumatic cylinder is used it will operate with sudden

jerks. After one full travel in both directions the cylinder will operate at

normal speed.

8.

Check for air leaks.

9.

Adjust the screw on top of the oiler to release one drop of oil for every six (6) full up and down cycles of a roller

arm pneumatic cylinder.