TROUBLESHOOTING

44

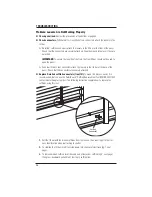

Problem: Panels Won’t Stay Closed

■

Check the Duracatch

™

panel lock.

Check to ensure that the panel lock plunger is seated

properly in the panel lock ramp. Possible problems include:

➤

The panel lock plunger is too far inside the panel. Adjust the plunger as described in

step 6 on page 40.

➤

The plunger does not sit in the “dip” in the panel lock ramp. Reposition the ramp, if

necessary. Refer to steps 1 through 5 on page 40.

➤

Check plunger and stile cap alignment. The plunger is designed to lock into grooves on

the stile cap to prevent unwanted rotation. If they are not aligned, the plunger will remain

inside the cap. To adjust, use a Robertson screwdriver to rotate the plunger as described

on page 9 until it is properly aligned and able to extend beyond the stile cap.

■

Check the number of magnets.

If magnets are used for closure, check that there are two

per panel, one at the top and one at the bottom. Refer to the magnet installation section on

page 41. (

Note:

Café style shutters use only one magnet per panel.)

■

Check magnet contact.

If magnets are used for closure, check that the magnets and

strike plates have full contact with each other. Possible problems include:

➤

The magnet and strike plate are not aligned. The magnet or strike plate may need to be

moved to achieve proper alignment. Refer to the magnet installation section on page 41.

➤

The magnet is at a slight angle, with only one side of the magnet touching the strike

plate. Loosen one of the screws on the magnet to allow it to be straightened so that it

makes full contact with the strike plate.

➤

The strike plate is not flush with the panel, so that only one side touches the magnet.

Adjust the screws so that the strike plate becomes flush with the panel.

■

Check panel load.

Load is created when the installation is not square. This places load

on the stile, which can force the panel to open with a spring-back effect. If the load is

excessive, the louvers may be difficult to close, as well. Possible solutions include:

➤

If load is detected with framed applications, tighten or loosen the installation screws on

the frame. (Do not use shims.) Start by removing all the installation screws except for the

top. Re-install the bottom installation screw until there is no load. Continue with all other

installation screws, one at a time, checking for load after each one.

➤

If there is load on a bi-fold panel, remove the second bi-fold panel and resolve the

problem with the first hinged panel as described above. Then re-attach the second panel

and check that the problem has been resolved.

➤

If load is detected with unframed applications, shim the hinges to square the panels.

Remove all hinge pins except for the top and bottom. Shim those hinges as needed until

the problem is resolved. Continue with the other hinges, one at a time, checking for load

after each one.