TROUBLESHOOTING

45

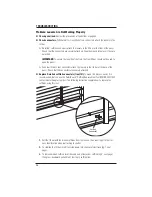

Problem: Panels Won’t Stay Closed (continued)

■

Check for obstructions that prevent panels from closing.

Possible problems include:

➤

Window cranks can prevent panels from closing. Take the crank off the rotator and

see if the panel is still obstructed. If the panel closes, replacing the window crank with

a T-crank can often solve the problem. Otherwise, build-out may be required to add

clearance. For panels without a frame, an extension hinge may be used to bring the

panel into the room an extra

5

/

8

".

➤

Window locks are other possible obstructions. Add clearance as described above.

➤

Patio door handles can prevent louvers from opening. If a handle stops a panel from

closing, the shutter must be built out.

➤

Bowed sills or casements can prevent inside-mounted shutter panels from closing if the

narrowest height and width measurements were not ordered. Double-check the inside

measurements and compare them with the measurements ordered and received.

■

Check for a twisted panel.

Panel stiles can sometimes be twisted by weight leaned

against it or by extreme heat. Fortunately, the polysatin material can be “tweaked” back

to its original shape with gentle force. To do this, use your hand to support the middle of

the panel’s outside stile and bend the top or bottom back into position until the panel

remains closed.

Problem: Panels Are Too Tight

■

Check that the frame is installed properly.

If the frame is not installed correctly, it may

cause the inside opening of the frame to be too narrow at a specific point, causing the

panels to be too tight. To check if the installation screws have been tightened the correct

amount, measure the top or bottom frame width and compare it to the width where the

panel appears to be too tight. Adjust the installation screws to square the frame.

■

Check that the panel is in the correct opening.

When multiple windows are of similar

size, panels can sometimes be placed into the wrong opening or with the incorrect panel

grouping. Check the labels and order form instructions to ensure that the panels are in the

correct opening and with the correct panel group.

■

Classic Z-Frame or Modern Z-Frame with rubber flex: remove the rubber flex from

one side of the frame.

If the opening is smaller than expected and installation screws do

not pull the frame straight, it may be necessary to remove the rubber flex from the back of

one or more sides of the frame. This can be done easily and safely by making a small cut

into the rubber flex material at one end of the frame, then peeling the rubber flex off the

frame.