Page 6 of 24

Hunting Energy Services (Well Intervention) Ltd

1.0 Health and Safety

1.1 General

Personnel using this manual to perform maintenance should have basic training in the following

disciplines:

Manual handling

MSDS and COSHH

Use of workshop equipment

Use of hand tools (PUWER)

Other basic courses may be required depending on regulations in the location/region that the

equipment is being used.

Safety is everyone’s responsibility, anyone can stop an operation should they deem an act unsafe no

matter what their position is within an organisation.

By following this document, using hand tools correctly, and following working practices the risk of

injury will be reduced to negligible.

CAUTION

Read service manual before operating

Observe all safety precautions

This system is capable of producing high fluid pressures - appropriate considerations are

required

Check that only qualified personnel are in immediate area around equipment

Suitable PPE must be worn at all times

Do not try to tighten or loosen connections under pressure

Do not weld, file or use metal stamps on the pressure equipment - these can create cracks

which could result in structural damage/failure

Do not over tighten manual/service valves (hand tight only).

Do not attach anything to this equipment unless you are sure of its pressure rating

Watch for trapped pressure. Bleed off fully before breaking down tool

Observe the maximum allowable operating pressure of all system components.

Observe the operating conditions of components.

Never stand under suspended loads or in the lifting area!

Summary of Contents for X-Over

Page 1: ...X Over Tool Manual Manual Revision Prepared Checked Approved Date C P Kinnaird 09 06 2017 ...

Page 15: ...Page 15 of 24 Hunting Energy Services Well Intervention Ltd Annex I Quick Union Table ...

Page 16: ...Page 16 of 24 Hunting Energy Services Well Intervention Ltd ...

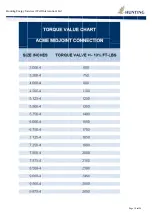

Page 17: ...Page 17 of 24 Hunting Energy Services Well Intervention Ltd Annex II Torque Value Chart ...

Page 18: ...Huntin ng Energy Se ervices Well l Intervention n Ltd Page 18 o of 24 ...

Page 19: ...Page 19 of 24 Hunting Energy Services Well Intervention Ltd Annex III API Flanges ...

Page 20: ...Page 20 of 24 Hunting Energy Services Well Intervention Ltd ...