16

Operator's Manual

26750TSC Compact Tiller

For additional information email

info@ardisam.com

or call 800-345-6007 M-F 8-5

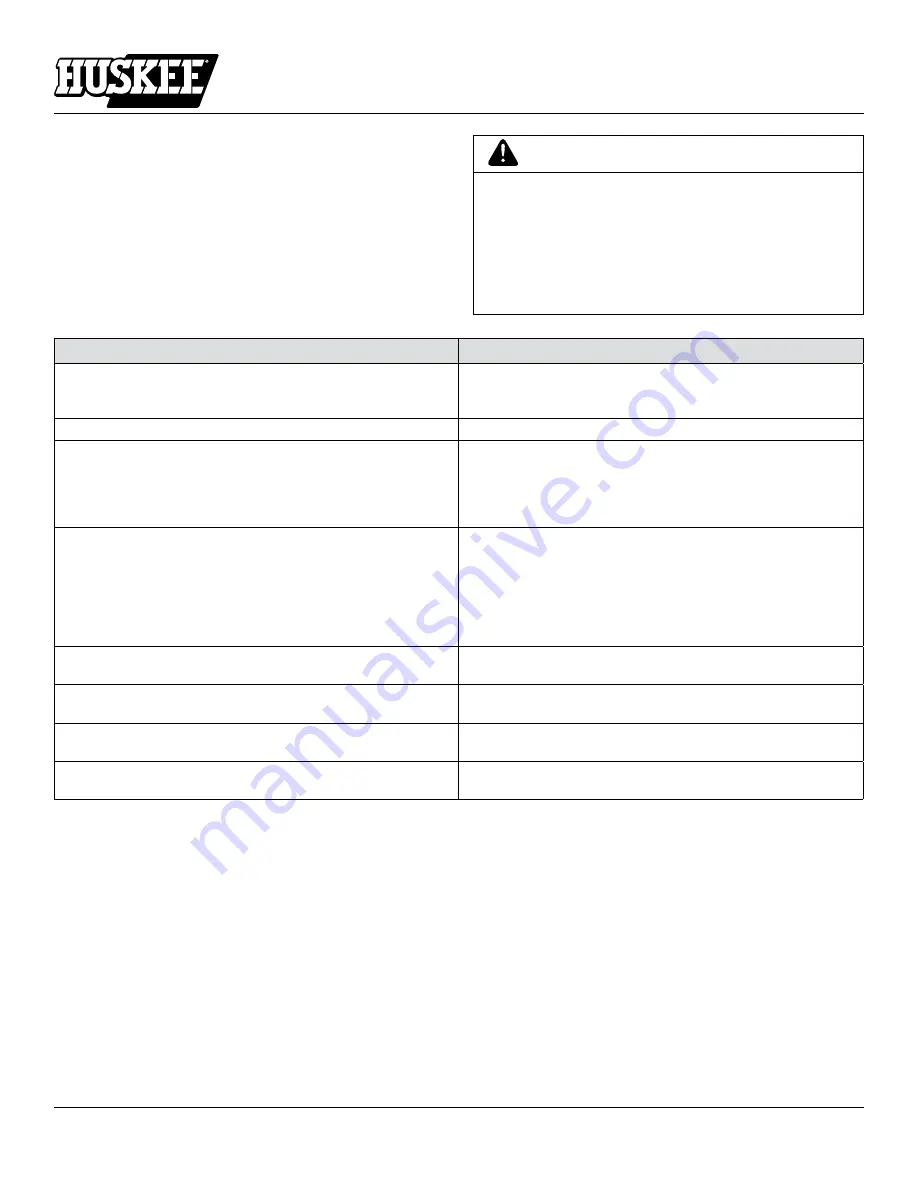

TROUBlESHOOTING aND REPaIR

TROUBlESHOOTING GUIDE

While normal care and routine maintenance will extend the life

of your rototiller, prolonged or constant use may eventually

require that service be performed to allow it to continue oper-

ating properly. The troubleshooting guide below lists the most

common problems, causes and remedies.

PROBlEm

REmEDY/aCTION

Engine will not start

• Add gas to gas tank.

• Connect spark plug wire to spark plug

• Throttle must be positioned at choke for a cold start

Engine runs rough, floods during operation

• Clean or replace air cleaner

Engine is hard to start

• Drain old fuel and replace with fresh. Use gas stabilizer at end of

season

• Make sure spark plug wire is securely attached to spark plug

• Drive safety control lever must be released to neutral to start the

engine

Engine misses or lacks power

• Raise the tines for shallower tilling by raising the depth

regulator lever

• Clean or replace air cleaner

• Improper carburetor adjustment, take to authorized

engine service center

• Replace spark plug and adjust gap

• Drain and refill gas tank and carburetor

Tiller moves forward during starting

• Drive safety control lever must be released to neutral

to start the engine

Tiller is difficult to control when tilling

(machine jumps or lurches forward)

• Lower engine speed in hard ground

• Lower the depth regulator for greater control of the tiller

Belts squeal in forward operation

• Adjust belt tension

• Replace drive belt

Excessive heat build up in transmission/tine area during tilling

• Remove vegetation

• Check transmission lubrication and fill if needed

WaRNING

PRaCTICE SaFETY aT all TImES. ENGINE mUST BE

TURNED OFF aND allOWED TO COOl, aND SPaRK

PlUG WIRE mUST BE DISCONNECTED aND SECURED

BEFORE aTTEmPTING aNY maINTENaNCE OR REPaIR.

FaIlURE TO COmPlY WITH THIS SaFETY REQUIREmENT

CaN RESUlT IN SERIOUS PERSONal INJURY TO YOU

OR BYSTaNDERS.