21

5. Piston

(See Table 7 for Piston weights)

Note:

For large hammers, you may wish to stand the hammer upright with proper

support, and pull the piston upward using a lifting device.

a. Attach an eyebolt to the top of the piston and pull out together with cylinder sleeve

toward the top.

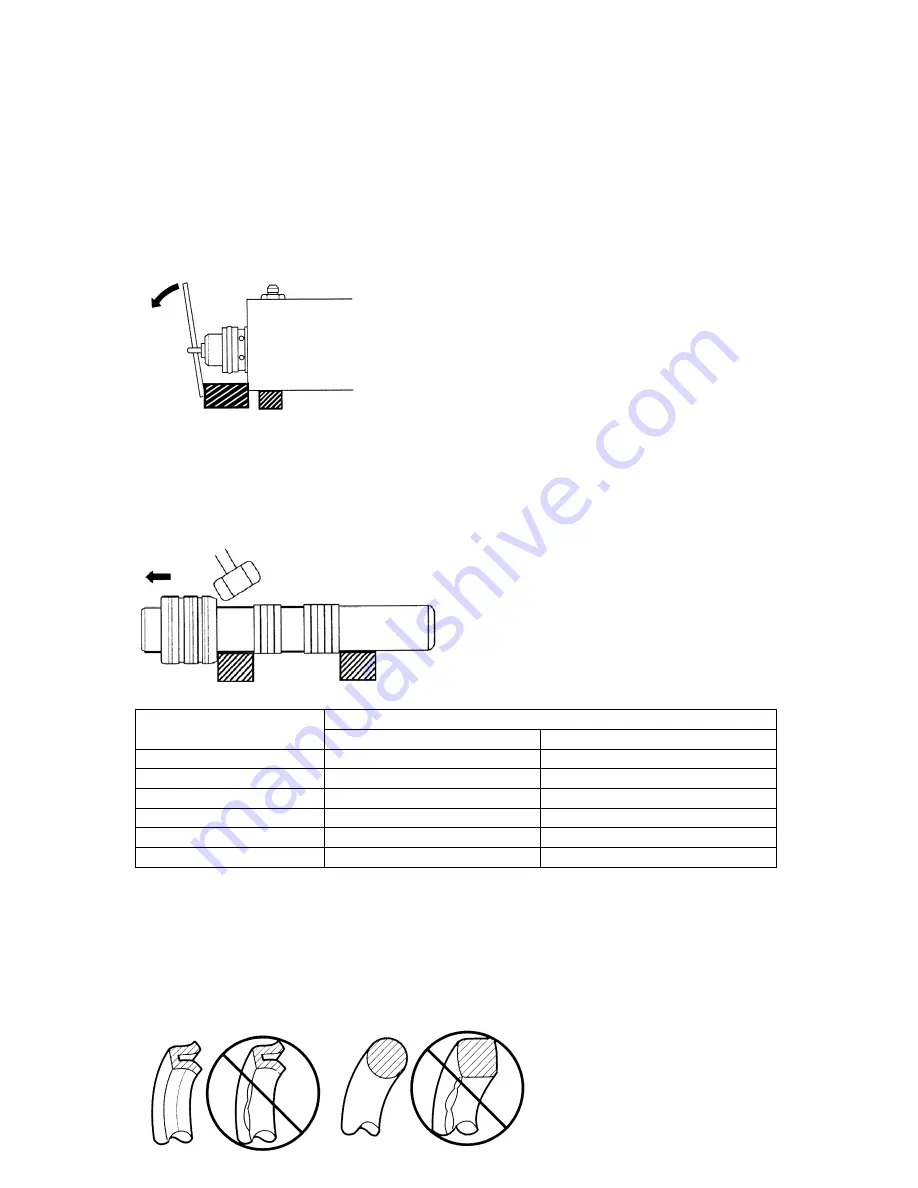

b. It may be useful to use a pry bar as a lever as shown in Figure 14. Be careful to

not damage the piston.

Figure 14. Removing the piston.

6. Cylinder

sleeve

Remove the cylinder sleeve from the piston. A plastic hammer or nylon bar can be used

for removal as shown in Figure 15. Do not force the cylinder sleeve. Tap uniformly on

all sides of the sleeve.

Figure 15. Removing Cylinder Sleeve

Note:

Support piston on wood blocks.

Table. 7. Piston Weights

WEIGHTS

HAMMER MODEL

kg lbs.

HH100

5.8

12.7

HH150-2 6.0

13.2

HH300-2 9.7

21.3

HH500-2 10.0

22.0

HH750-2 17.1

37.6

HH1000-2

25.4

55.9

INSPECTION OF PARTS

1. Seals

Seals that are deformed, scratched, worn or aged should be replaced (see Figure 16).

It is recommended that all seals be replaced when disassembling the hammer.

Figure 16. Seal Conditions

Summary of Contents for HH100

Page 1: ...HUSKIE HYDRAULIC HAMMERS SERVICE MANUAL HH100 HH150 2 HH300 2 HH500 2 HH750 2 HH1000 2 ...

Page 2: ...2 ...

Page 33: ...33 9 PARTS LIST AND ILLUSTRATIONS HH100 HH150 2 HH300 2 HH500 2 HH750 2 HH1000 2 ...

Page 35: ...35 HH100 HAMMER Effective 07 09 ...

Page 37: ...37 ...

Page 39: ...39 HH150 2 HAMMER S N 001 099 2B2 1000 UP Effective 07 09 ...

Page 41: ...41 ...

Page 43: ...43 HH300 2 HAMMER S N 001 099 2E2 1000 UP Effective 07 09 ...

Page 47: ......

Page 49: ...49 HH500 2 HAMMER S N 001 099 2R2 1000 UP Effective 07 09 ...

Page 55: ...55 HH750 2 HAMMER S N 001 099 2F2 1000 UP Effective 07 09 ...

Page 59: ...59 ...

Page 61: ...61 Effective 07 09 HH1000 2 HAMMER S N 001 099 2H2 1000 UP ...