www.spartacogroup.com

800-860-6170

8

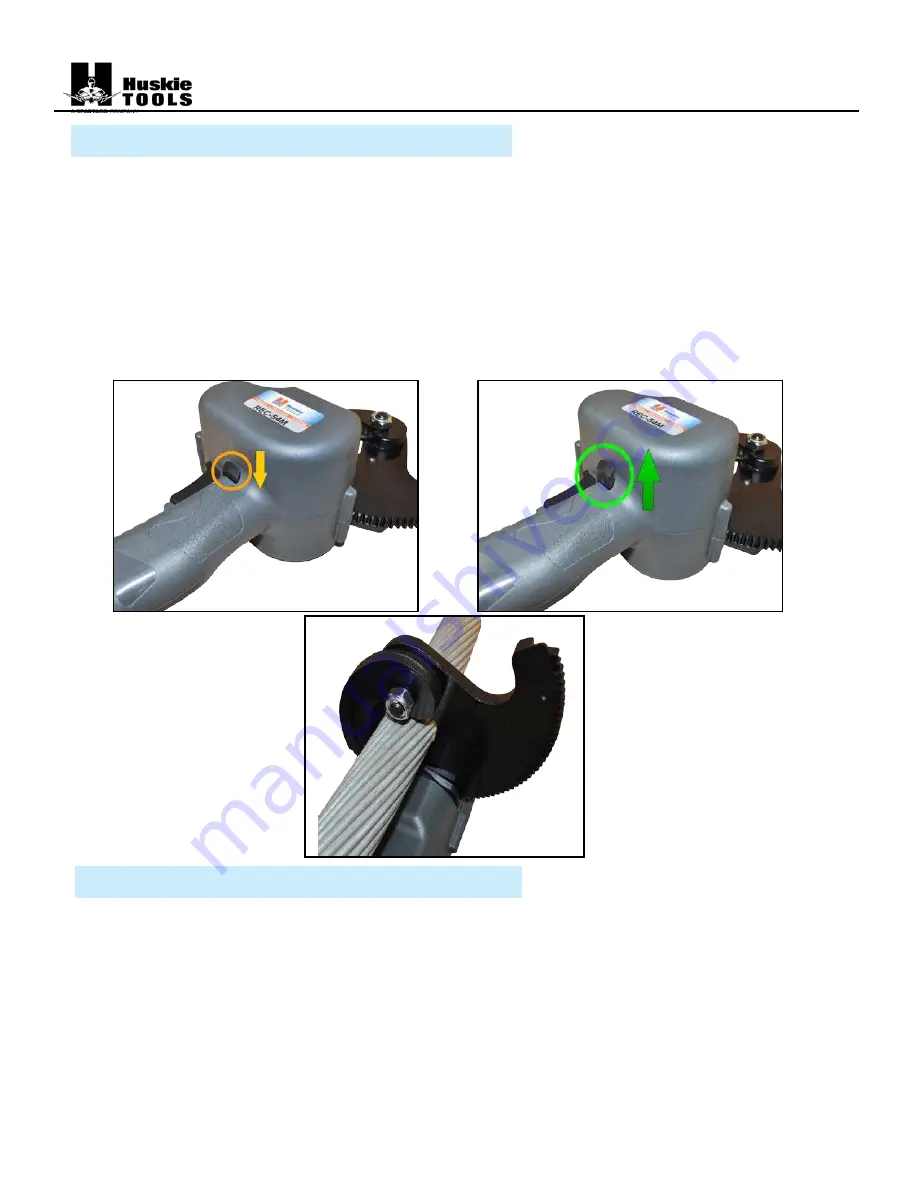

CUTTING

1. Select the appropriate control setting [Forward (

A

) or Reverse (

B

)] by activating toggle

switch located above the trigger.

2. Be sure that material being cut is within the specified cutting capacity of the tool.

3. Place the material to be cut between the blades and press the advance trigger until blades

hold the material in place.

4. Check material for proper alignment to the cutting blades. It should be at a 90° degree

angle to the blades (

C

). Any other angle will cause the blades to spread apart and possibly

break.

5. Continue to advance the blades until the material is cut. Once cut, select the Reverse on the

toggle switch to retract the blades.

OPERATING INSTRUCTIONS

MAINTENANCE AND INSPECTION

1. Daily maintenance is required to ensure that the tool is kept in good working condition.

2. Sharpen blades occasionally with a sharpening stone on the back side of the blades to

remove any burrs that may occur.

3. Do not store the tool in a humid environment.

4. Wipe away any excess oil with a soapy cloth.

5. Provided that maintenance of the tool is carried out regularly, the tool should provide

many years of service.

6. Should you experience any difficulty with the operation and maintenance of this tool,

contact Huskie’s technical support department at 1-800-860-6170.

A

B

C

[All materials should be at a 90°

angle to the blades as shown in

figure

C

.]

Forward Toggle

Reverse Toggle

Summary of Contents for REC-54ACM

Page 10: ...www spartacogroup com 800 860 6170 10 BREAKDOWN...

Page 11: ...www spartacogroup com 800 860 6170 11 PARTS LIST...

Page 13: ...NOTES...

Page 14: ...NOTES...

Page 15: ...NOTES...