www.huskietools.com

10

TROUBLESHOOTING GUIDE

1.

Problem:

Small wire strands or pieces of cable or debris get jammed between the cutter head and

blade, not allowing the blade to retract.

Solution:

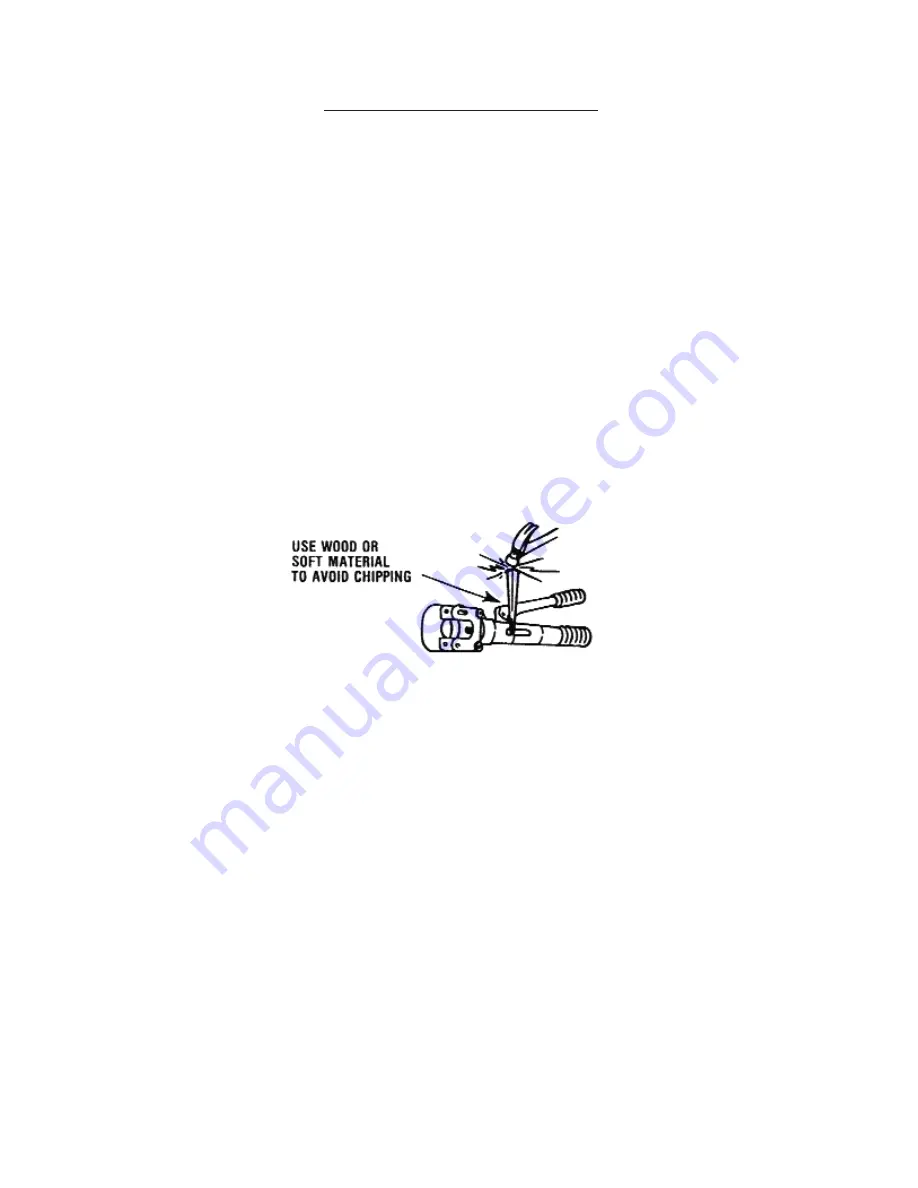

A) Hold release lever down while tapping on the ram with a block of wood and a ham

mer. If this does not work or tool continues to hang up, proceed to step B.

B) Remove blade screw and release the ram. Then disassemble cutter head and remove burs from

both blade and head shear, using a flat grinding stone on the rolled edge.

Do not sharpen like

a knife - leave cutting edge flat!

2.

Problem:

Blade is advanced under pressure with no load and the release lever

Solution:

A) Use both hands to depress lever using body weight and the ground or other strong

surface for support. If this does not work, proceed to step B.

B) Lay tool flat on the ground or other strong surface and hit release lever with a block of wood and

a hammer to release pressure.

3. Problem: Tool will not advance.

Solution:

A) Remove body handle and check oil reservoir for proper fluid level. The oil should be

the top of the reservoir when the cap is removed. Be sure the tool is fully retracted before removing

cap.

B) After storing for a long period of time, or occasionally when the tool is new, a check ball may be

stuck not allowing it to advance the blade. Invert the tool and rap the cutter head sharply on the

ground. Do this several times, then pump handle to advance the blade.