www.huskietools.com

8

1. Before cutting, make sure the material being cut is within the proper cutting capacity of the tool

being used.

2. Open cutter head by lifting latch or removing lock pin, depending on the model being used.

3. Insert material between cutter head and blade and secure latch. It is important that you check the

latch for proper engagement before continuing with the cut.

Failure to secure the latch can result

in severe tool damage and personal injury.

4. Align the material at a 90 degree angle to the blade. This will ensure a proper cut with minimal

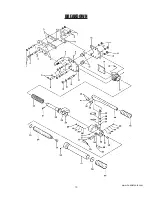

distortion. If the material is cut at any other angle, severe blade damage may occur. Refer to

diagram in the general instructions for proper alignment.

5. Proceed by pumping handle to advance blade. Once blade has made contact with the material,

check alignment once again for proper angle. Continue to pump handle and cut material.

6. Once the cut is made, the release lever on the side of the tool body can be depressed to retract the

blade. On the model S-85 cutter, the pump handle must be rotated 90 degrees clockwise and then

closed to depress release pin located under the handle.

7. These cutters do not have a by-pass cartridge like our compression tools, so they should be

released once the cut is made and not continued to be advanced. If the tool is advanced under

pressure with no load, it is difficult to release the blade. Refer to the troubleshooting on page three

if this condition occurs.

8. Always wear eye protection and any other specified safety equipment when cutting. Be sure sur

rounding area is clear, as hardened metals may fly apart when severed.

9. For EHS guy wire or bridge strand, use models S-24CC or S-32CC only! The use of any other S-

series cutter will result in severe blade damage and may cause personal injury.

10. Model S-85 cutter is designed for use on non-ferrous metals only! Do not cut steel or severe tool

damage and personal injury may occur.

S-SERIES OPERATING INSTRUCTIONS