20

Maintenance (continued)

4

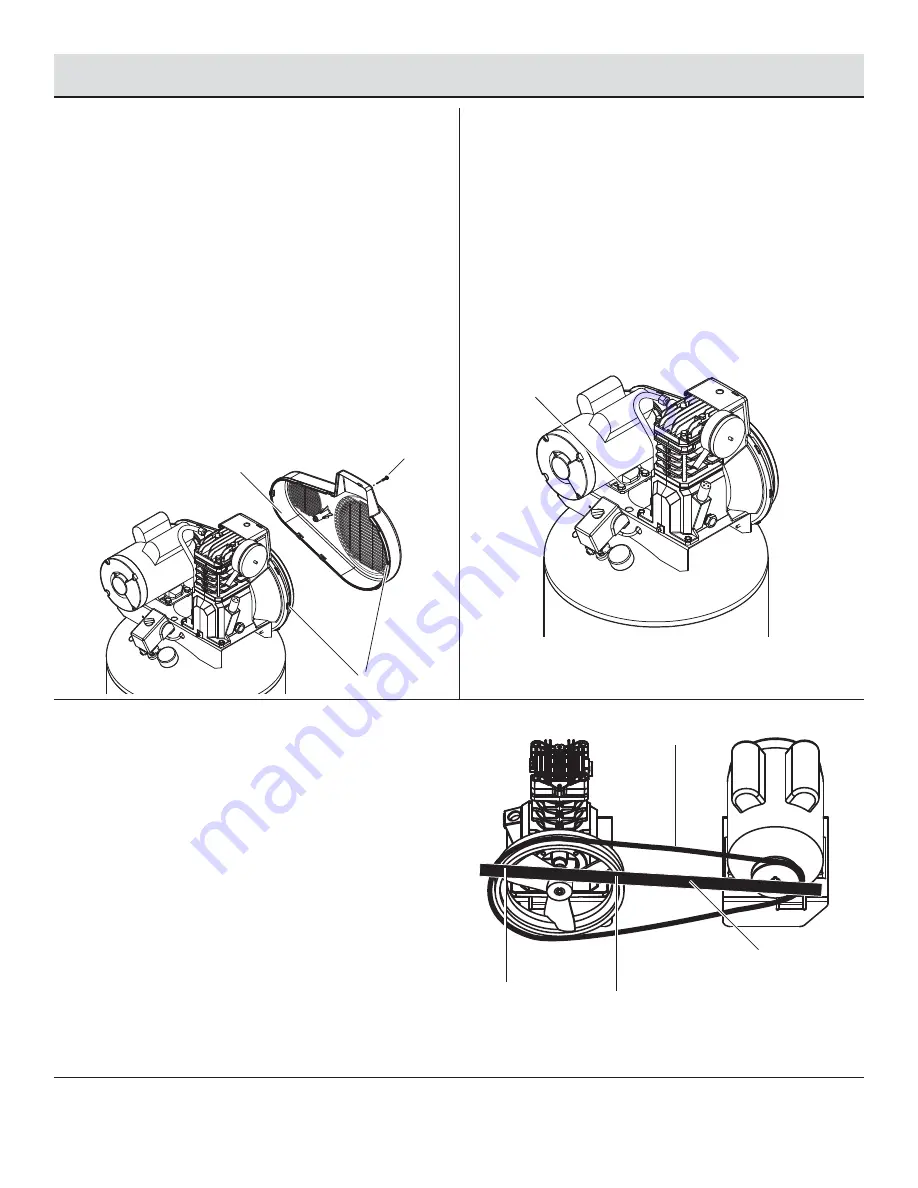

Checking the belt

□

Remove the beltguard screw (1).

□

Remove the front beltguard (2). The beltguards are held

together by pressure snap-latches (3). Wedge a fl athead

screwdriver between the beltguards at the snap-latches.

□

Wedge a screwdriver at the other snap-latch junctions.

Twist and separate the snap-latches until the front

beltguard comes completely off.

□

If the belt appears to be in working order and has no

signs of damage, return the front beltguard to the original

position and snap it back in place. Tighten the beltguard

screw.

□

If the belt needs to be replaced, move on to the next step.

□

If the belt does not need to be replaced, move to step 6.

5

Removing the belt

□

Loosen (but do not remove) the four bolts (1) holding the

motor in place.

□

Shift the motor towards the pump. The belt should be slack

and easily removed.

□

Replace the belt.

□

Move the motor back to the original position to create belt

tension.

□

Tighten the motor bolts.

6

Aligning / tensioning the belt

□

Lay a straightedge (1) against the face of the fl ywheel

touching the rim at two places (2,3).

□

Adjust the flywheel or motor pulley so that the belt (4) runs

parallel to the straightedge. Use a gear puller to move the

pulley on the motor shaft. Tighten the setscrew after the

pulley is positioned.

□

Adjust the motor’s distance from the pump if needed.

□

Belt tension is determined by how much the belt moves

when weight is applied. The belt should move no more

than 3/8 to 1/2 in. downward if normal thumb pressure is

placed on it.

□

Tighten the motor bolts once the proper belt tension is

achieved.

□

Reattach the belt guard.

1

2

4

3

1

2

3

1