10

FUEL VALVE

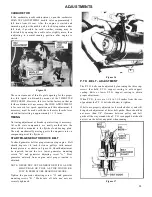

A fuel shut off valve is in the line from the fuel tank to the

carburetor. See Figure 12 for location.

Figure 12

FUEL FILTER

There is also a fuel filter in the line from the fuel tank. See

Figure 12 for location. This filter can be opened up for

cleaning. To open: close fuel shut-off valve. Turn the two

halves counterclockwise to open. See Figure 13 for opened

filter.

NOTE: To reclose, twist the two halves counterclockwise

each about one half turn before assembling. Then

place two halves together and close by turning

clockwise until they are securely tightened.

Figure 13

BATTERY

Keep cables and terminals clean. Apply a light coat of

petroleum jelly or oil for protection. Check battery bracket

for corrosion and clean.

The battery terminal boot supplied on the positive battery

cable

must

be installed over the battery terminal after the

cable is secured to the positive battery post. This is to

prevent accidental shorting. See Figure 14. ALWAYS

POSITION CABLE TERMINALS AS SHOWN IN FIGURE

14.

ELECTRIC STORAGE BATTERIES GIVE

OFF HIGHLY FLAMMABLE HYDROGEN

GAS WHEN CHARGING, AND CONTINUE

TO DO SO FOR SOME TIME AFTER

RECEIVING A STE ADY CHARGE. DO NOT UNDER

ANY CIRCUMSTANCES ALLOW AN ELECTRIC SPARK

OR AN OPEN FLAME NEAR THE BATTERY. DO NOT

LAY TOOLS ACROSS BATTERY TERMINALS AS THIS

MAY RESULT IN A SPARK OR SHORT CIRCUIT

WHICH MAY CAUSE AN EXPLOSION. BE CAREFUL TO

AVOID SPILLING ANY ELECTROLYTE ON HANDS OR

CLOTHING.

Figure 14

NOTE: WHEN SERVICING THE BATTERY, BE SURE

BATTERY CABLES ARE DISCONNECTED BE-

FORE ATTEMPTING REMOVAL OF THE BAT-

TERY FROM THE TRACTOR. ALWAYS DIS-

CONNECT NEGATIVE (-) CABLES FIRST.

WHEN INSTALLING THE BATTERY, ALWAYS

CHECK THE POLARITY OF THE BATTERY

TERMINALS TO BE SURE THE BATTERY IS

NOT REVERSED. THE NEGATIVE TERMINAL

(-) IS GROUND. ALWAYS CONNECT THE

NEGATIVE TERMINAL (-) LAST. SHOULD IT

BECOME NECESSARY TO REMOVE THE BAT-

TERY, WHEN REINSTALLING IT: (1) PLACE

HOLD DOWN RODS IN PLACE. (2) TIGHTEN

WING-NUTS FINGER TIGHT ONLY, TO AVOID

POSSIBLE DAMAGE TO BATTERY CASE.

The electrolyte (acid and water) in each cell should be at

triangle level at all times to prevent battery failure. When

the electrolyte is below this level,

add pure, distilled water.

UNDER NO CIRCUMSTANCES ADD ANY SPECIAL

BATTERY "DOPES," SOLUTIONS OR POWDERS OR

EXOTIC ADDITIVES: THIS VOIDS WARRANTY.

PNEUMATIC TIRES

Keep both front and rear tires inflated evenly. Under no

circumstances should tire inflation be less than 8 pounds,

nor more than 12 pounds. Check air pressure regularly with

a low pressure gauge. Operating with incorrect pressures

may damage tires.

See Trouble Shooting Guide on page 17 for additional

information.

PREVENTIVE MAINTENANCE Continued)

Summary of Contents for 1254-06

Page 1: ......

Page 19: ...18 ...

Page 22: ...LUBRICATION AND MAINTENANCE RECORD DATE PERFORMED DESCRIPTION OF MAINTENANCE HRS RUN ...

Page 23: ......

Page 24: ......