Extension Cords

NOTE: USE EXTRA AIR HOSE INSTEAD OF AN EXTENSION CORD TO

AVOID VOLTAGE DROP AND POWER LOSS TO THE MOTOR. IF AN

EXTENSION CORD MUST BE USED, BE SURE IT IS:

3-wire extension cord that has a 3-blade grounding plug, and a 3-slot receptacle that

will accept the plug on the product

in good condition no longer than 30 feet

14 gauge (AWG) or larger. (Wire size increases as gauge number decreases.

14, 12, 10, and 8 AWG may also be used.

Voltage and Circuit Protection

Refer to the specification chart for the voltage and minimum branch circuit

requirements.

Risk of Unsafe Operation. Certain air compressors can be

operated on a 15 A circuit if the following conditions are met.

1. Voltage supply to circuit must comply with the National Electrical Code.

2. Circuit is not used to supply any other electrical needs.

3. Extension cords comply with specifications.

4. Circuit is equipped with a 15 A circuit breaker or 15 A time delay fuse.

NOTE:

If compressor is connected to a circuit protected by fuses, use only

time delay fuses. Time delay fuses should be marked "D" in Canada and "T"

in the US.

If any of the above conditions cannot be met, or if operation of the

compressor repeatedly causes interruption of the power, it may be necessary

to operate it from a 20 A circuit. It is not necessary to change the cord set.

Please contact a qualified technician.

16

INSTALLATION

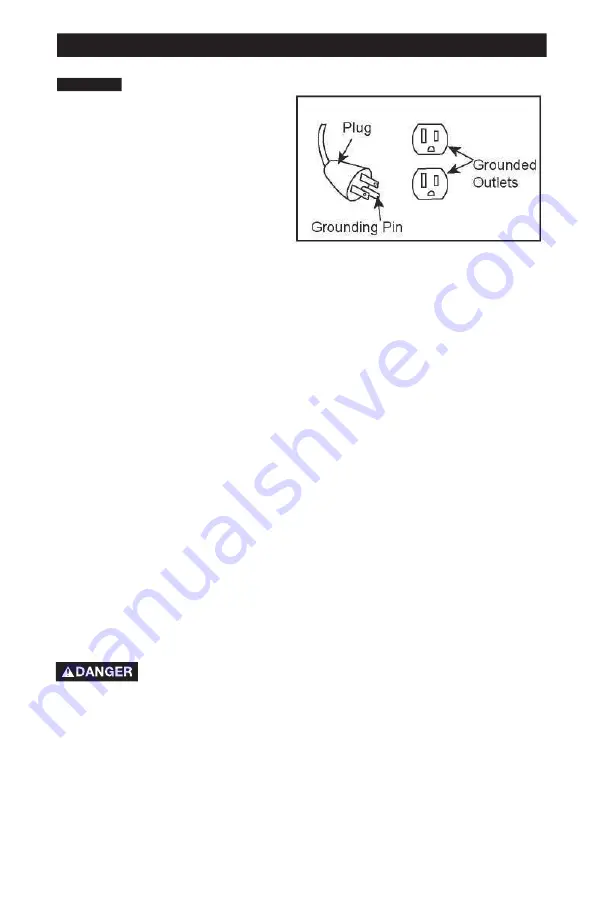

GROUNDING INSTRUCTIONS (Fig. F)

DANGER!

IMPORTANT:

The outlet being used must be installed and grounded in accordance

with all local codes and ordinances.

2. Make sure the outlet being used has the same configuration as the grounded plug.

DO NOT USE AN ADAPTER.

(See illustration)

4. If these grounding instructions are not completely understood, or if in doubt as to

whether the compressor is properly grounded, have the installation checked by a

qualified electrician.

Risk of Electric Shock. IMPROPER GROUNDING CAN RESULT IN ELECTRICAL

SHOCK. When repair or replacement of the cord or plug is required, do not

connect the grounding wire to either flat blade terminal. The wire with insulation

having an outer surface that is green with or without yellow stripes is the

grounding wire. Do not modify the plug provided. If it does not fit the available

outlet, a correct outlet should be installed by a qualified electrician. Repairs to

the cord set or plug MUST be made by a qualified electrician.

Risk of Electric Shock. In the event of a short circuit, grounding reduces

the risk of shock by providing an escape

wire for the electric current. This air

compressor must be properly grounded.

The portable air compressor is equipped

with a cord having a grounding wire

with an appropriate grounding plug

(see following illustrations). The plug

must be used with an outlet that has

been installed and grounded in accor-

dance with all local codes and ordina-

nces.

1. The cord set and plug with this unit contains a grounding pin. This plug MUST be

used with a grounded outlet.

Fig. F

Summary of Contents for 41214

Page 27: ...27 PART LISTS ...