22

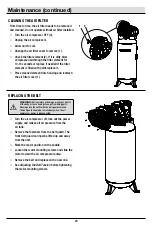

MOTOR PULLEY/FLYWHEEL ALIGNMENT

The air compressor flywheel and motor pulley must be

in-line (in the same plane) within 1/16 in. (1.6 mm) to

assure belt retention within the flywheel belt grooves.

To check the alignment, perform the following steps:

□

Turn the air compressor off, lock out the power

supply, and relieve all air pressure from the air

tank.

□

Remove outer belt guard.

□

Place a straightedge (4) against the outside

of the flywheel (1) and the motor drive

pulley hub (3).

□

Measure the distance between the edge of the

belt (2) and the straightedge at points A1 and A2.

The difference between measurements should

be no more than 1/16 in. (1.6 mm).

□

If the difference is greater than 1/16 in.

(1.6 mm), loosen the set screws holding the

motor drive pulley (3) to the shaft and adjust the

pulley’s position on the shaft until the A1 and A2

measurements are within 1/16 in. (1.6 mm) of

each other.

□

Tighten the motor drive pulley set screws. Torque

to 115-125 in-lbs (13.0-14.1 Nm)

□

Visually inspect the motor drive pulley to verify

that it is perpendicular to the drive motor shaft.

The points (B1 and B2) should appear to be

equal. If they are not, loosen the set screws

of the motor drive pulley and equalize B1 and

B2, using care not to disturb the belt alignment

performed previously.

□

Retighten the motor drive pulley set screws.

Torque to 115-125 in-lbs (13.0-14.1 Nm).

□

Reinstall the outer belt guard.

A1= A2 (MEASURED)

B1= B2 (VISUAL)

A1

A2

B1

B2

1

2

3

4

Maintenance (continued)