25 HUSKYTOOLS.com

Please contact 1-888-43-HUSKY for further assistance.

Problem

Possible Cause

Solution

There is excessive belt wear.

□

The belt is too loose.

□

Check the belt tension.

□

The belt is too tight.

□

Check the belt tension.

□

The pulley is loose.

□

Align the pulley/flywheel. Correct the belt

tension. Torque the set screws.

□

The pulley is misaligned.

□

Align the pulley/flywheel.

There is oil and/or moisture

in the tank and/or air lines.

□

The connections (fittings,

tubing, etc.) are loose and

leaking.

□

Check all the connections with a soap

and water solution and tighten.

□

The drain valve is loose

or open.

□

Tighten the drain valve.

□

The check valve is leaking.

□

Bring the compressor to a service center.

There is excessive moisture

in the discharge air.

□

There is excessive water in

the air tank.

□

It is normal for oil lube air compressor

pumps to release some oil into the tank

and air lines. Air compressors will also

generate water condensation that will

form in the tank and air lines. Install

water and oil filter traps when needed.

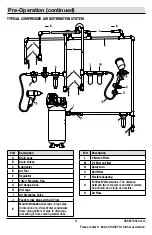

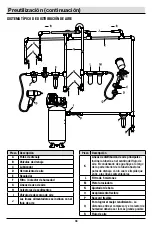

The

Typical Compressed Air Distribution

System

section provides a guideline.

Contact or call Husky Customer Service

for more information.

□

The oil blow-by has

accumulated in the pump.

□

IMPORTANT: If the tank or air lines have

excessive water and/or oil, bring the

compressor to a service center.

The fuses blow or the circuit

breaker trips repeatedly.

□

The incorrect fuse size is

being used, or the circuit is

overloading.

□

Verify the proper fuse size is being used.

□

Use time-delay fuses.

□

Disconnect other electrical appliances

from the circuit or operate the

compressor on its own branch circuit.

□

There are loose electrical

connections.

□

Verify the wiring connection inside the

pressure switch and the terminal box

area.

□

There is a defective check

valve or unloader.

□

Bring the compressor to a service center.

Troubleshooting (continued)