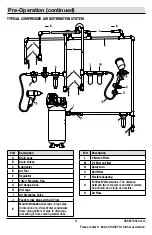

8

Part

Description

A

AUTO (I) / OFF (0) Switch:

Turn this switch in the “Auto (I)” position to provide automatic power to the

pressure switch and “Off (O)” to remove power at the end of each use.

B

Pressure Switch:

The pressure switch automatically starts the motor when the air tank pressure drops

below the factory set “cut-in” pressure. It stops the motor when the air tank pressure reaches the

factory set “cut-out” pressure.

C

Safety Valve:

If the pressure switch does not shut off the air compressor at its “cut-out” pressure

setting, the safety valve will protect against high pressure by “popping out” at its factory set pressure

(slightly higher than the pressure switch “cut-out” setting).

D

Tank Pressure Gauge:

The tank pressure gauge indicates the reserve air pressure in the tank.

E

Air Compressor Pump

: Compresses air into the air tank. Working air is not available until the compressor

has raised the air tank pressure above that required at the air outlet.

F

Drain Valve:

The drain valve is located at the base of the air tank and is used to drain condensation at

the end of each use.

G

Check Valve:

When the air compressor is operating, the check valve is “open”, allowing compressed air

to enter the air tank. When the air compressor reaches “cut-out” pressure, the check valve “closes”,

allowing air pressure to remain inside the air tank.

H

Pressure Relief Valve:

The pressure relief valve located on the side of the pressure switch is designed

to automatically release compressed air from the compressor head and the outlet tube when the

air compressor reaches “cut-out” pressure or is shut off. The pressure relief valve allows the motor

to restart freely. When the motor stops running, air will be heard escaping from this valve for a few

seconds. No air should be heard leaking when the motor is running or after the unit reaches “cut-out”

pressure.

SYSTEM COMPONENTS

Pre-Operation (continued)

A

G

D

B

C

E

L

N

M

I

O

H

P

K

J

F

E

L

N

M

I

O

H

P

K

J

F