Brute Electric Jack (4,500 & 3,000 lb)

with Smart Stop®

Read and follow all instructions. If you do not understand the proper use of the product, ask your dealer/

installer for assistance. Never remove any warning decals from the product.

®

Rev. 2019-12-17

www.huskytow.com

Made in China for / Fabriqué en Chine pour LKQ Specialty Products Group, Elkhart, IN 46516

© LKQ Specialty Products Group, 2019. All rights reserved. Tous droits reserves.

Warnrng:

Keep hWrds, feet Wrd body cleWa of the jWck Wrd taWnlea to Wvond the

ansk of nrjuay oa deWth!

Installation

Warnrng:

Befoae nrstWllWtnor, compWae the lnft cWpWcnty of the Husky

®

Baute wnth

youa taWnlea to ersuae sWfe opeaWtnor of the jWck.

1.

Park the trailer on a level surface and block the wheels.

2.

Support the trailer tongue by the frame with jack stands.

3.

If replacing an old jack, remove the old jack from the coupler, saving the washers and bolts.

4.

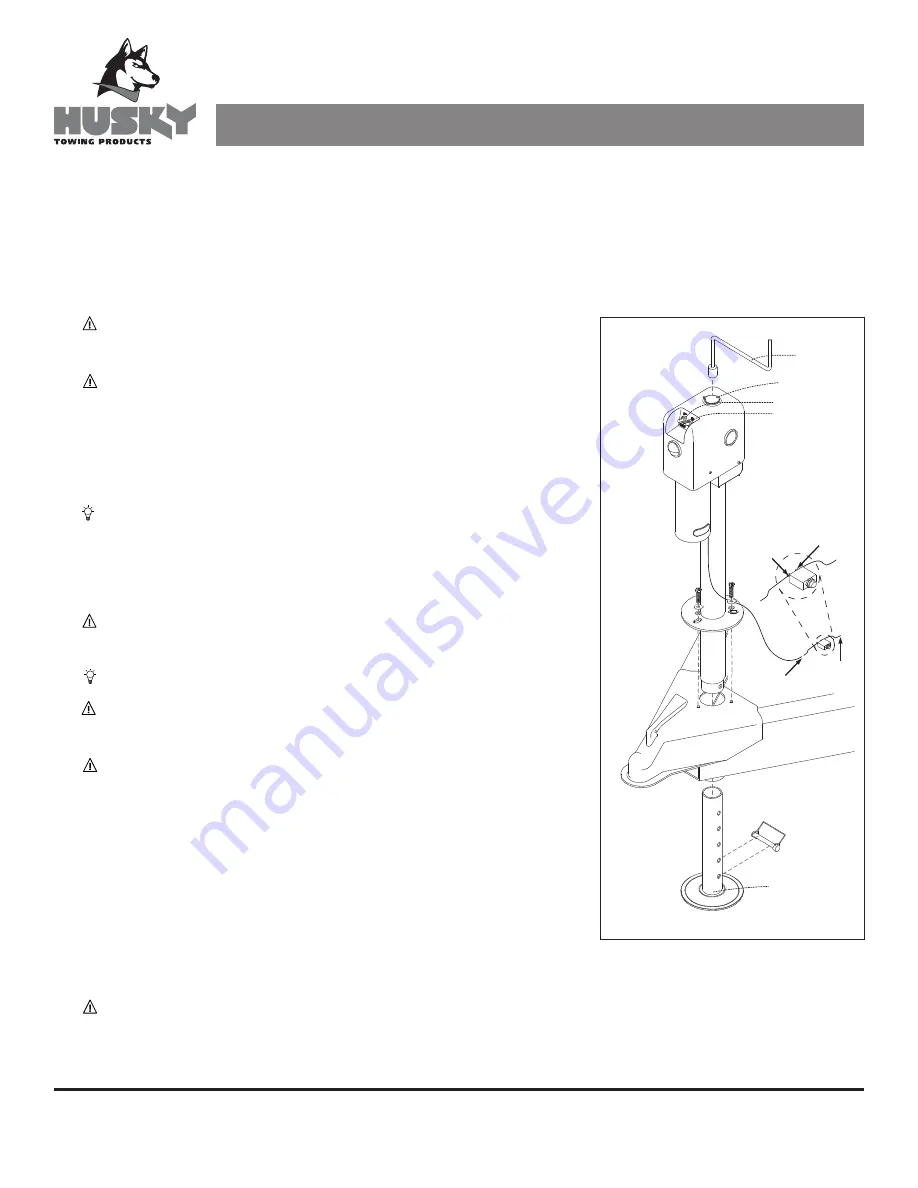

Insert the Husky

®

Brute into the jack hole and align the bolt holes so the motor housing is facing forward as shown

in Figure 1.

5.

Secure the jack with three (3) grade 5, 3/8”-16 UNC bolts and washers. Place the star washers between the flat

washers and the mounting plate as shown in Figure 1. The star washers are intended to penetrate through the

paint on the mounting plate to ensure direct metal to metal contact. Bolts should be tightened to 15–20 ft•lb.

npg:

The salvaged bolts from the old jack are acceptable for reuse if they are grade 5 and in

good condition.

6.

If a lower support plate is not already present, install one in the bottom of the trailer frame. Do not operate the

jack without a lower support plate.

7.

Install the manual reset circuit breaker by either crimping or soldering one of the wires to the jack lead (Black).

Connect the other wire to the positive terminal of the battery. The breaker should be located as close to the

battery as possible and stored inside the battery box. Since the jack is internally grounded, a ground wire is not

necessary.

Warnrng:

When using an extension wire, DO NOT use a wire smaller than #10 gauge.

Operation

1.

Park your trailer on a level surface and block all dolly and trailer wheels.

npg:

For nighttime hookups, flip the light switch ON to illuminate your work area.

2.

Before operating the jack, attach the foot with the 3/8” safety lock pin provided.

Warnrng:

Do not stack blocks under the jack’s foot to increase the height. Stacked blocks may

become unstable and fall.

3.

Extend the jack by pushing the operating switch

UP

. (With the HB4500R, you can press the UP button on the

remote control – see page 2 for remote control instructions.)

Warnrng:

Under heavy use, the internal circuit breaker may open, causing the motor to switch off.

In this case, release the operating switch, and wait 15 seconds for the breaker to reset

before resuming operation.

4.

Retract the jack by pushing the operating switch

DO N

. (With the HB4500R, you can press the DOWN button

on the remote control – see page 2 for remote control instructions.)

Noteg:

The jack will stop automatically at the end of the extension or retraction stroke. If you

attempt to extend or retract the jack and it does not respond, it may be at the end of the

stroke. If the jack fails to respond, try operating it in the opposite direction. If it will not

operate in either direction then see the troubleshooting guide.

5.

Before driving, remove the foot or position it in the highest position and completely retract the jack.

Manual Operation (for Back-Up & Emergency Use)

1.

Disconnect the jack from the power source. (Failure to disconnect the power could result in serious injury.)

2.

Remove the rubber access covers on the top of the jack and on the side of the motor cover.

3.

Insert the manual crank handle into the access hole on the top of the jack, engaging the drive screw.

4.

While holding the crank firmly in place, install the brake release handle on the brake lever and pull forward,

releasing the brake.

Specifications:

Models Applicable .........................HB4500; HB4500R; HB3000

Maximum Lift Capacity ...................4,500 lb / 3,000 lb (continuous use)

Retracted Height .............................31-3/8

Vertical Travel ................................18”

Power Requirements .......................12 Volt DC

Outer Tube Diameter ......................2¼”

Power Cord Length .........................6 ft of #10 Gauge Wire

Foot Pad Diameter ..........................5½”

LED Work Lights .............................On 3 sides for Easy Nighttime Hookups

Shipping Weight ............................HB4500 & HB4500R – 29 lb; HB3000 – 27½ lb

Tools and Components Required:

• A-Frame Coupler with Lower Support Plate

• Three (3) Grade 5, 1–1½” Long, 3/8”-16 UNC Bolts

• Three (3) 3/8” Flat Washers

• Three (3) 3/8” Star Washers (included)

• 9/16” Wrench

• Torque Wrench

• Wire Cutters

• Wire Strippers

• Crimpers OR Soldering Iron

Fnnuae 1

Manual Crank

Operating Switch

Light Switch

Circuit Breaker

“Line”

Terminal

“Load”

Terminal

“Line” to the

positive terminal

of the battery

“Load” to

the jack.

Rubber Access Cover

Adjustable Foot

Safety Lock Pin

Warnrng:

Always install the crank handle and hold it firmly in place before releasing the brake on a loaded jack. Due to the Husky

®

Brute’s low-friction ball screw,

if the crank is not held firmly in place, the jack may run away and the crank may spin dangerously when the brake is released.

5.

Rotate the manual crank handle counter-clockwise to extend the jack, and clockwise to retract it.

6.

When the jack is at the desired height, first re-engage the brake then remove the crank and brake release handle. Replace the rubber covers.