15

-!).4%.!.#%

!VOIDUSINGSOLVENTSWHENCLEANINGPLASTICPARTS-OST

PLASTICSARESUSCEPTIBLETODAMAGEFROMVARIOUSTYPESOF

COMMERCIALSOLVENTSANDMAYBEDAMAGEDBYTHEIRUSE

5SECLEANCLOTHSTOREMOVEDIRTDUSTOILGREASEETC

7!2.).'

$ONOTATANYTIMELETBRAKEFLUIDSGASOLINEPETROLEUM

BASEDPRODUCTSPENETRATINGOILSETCCOMEINCONTACT

WITHPLASTICPARTS#HEMICALSCANDAMAGEWEAKENOR

DESTROYPLASTICWHICHMAYRESULTINSERIOUSPERSONAL

INJURY%LECTRICTOOLSUSEDONFIBERGLASSMATERIALWALL

BOARDSPACKLINGCOMPOUNDSORPLASTERARESUBJECT

TOACCELERATEDWEARANDPOSSIBLEPREMATUREFAILURE

BECAUSETHEFIBERGLASSCHIPSANDGRINDINGSAREHIGHLY

ABRASIVETOBEARINGSBRUSHESCOMMUTATORSETC#ON

SEQUENTLYWEDONOTRECOMMENDEDUSINGTHISTOOLFOR

EXTENDEDWORKONTHESETYPESOFMATERIALS(OWEVERIF

YOUDOWORKWITHANYOFTHESEMATERIALSITISEXTREMELY

IMPORTANTTOCLEANTHETOOLUSINGCOMPRESSEDAIR

,5"2)#!4)/.

!LLOFTHEBEARINGSINTHISTOOLARELUBRICATEDWITHASUFFI

CIENTAMOUNTOFHIGHGRADELUBRICANTFORTHELIFEOFTHEUNIT

UNDERNORMALOPERATINGCONDITIONS4HEREFORENOFURTHER

LUBRICATIONOFTHEBEARINGSISREQUIRED

7!2.).'

7HEN SERVICING USE ONLY IDENTICAL (USKY REPLACEMENT

PARTS 5SE OF ANY OTHER PARTS MAY CREATE A HAZARD OR

CAUSEPRODUCTDAMAGE

7!2.).'

!LWAYSWEARSAFETYGOGGLESORSAFETYGLASSESWITHSIDE

SHIELDS DURING POWER TOOL OPERATION OR WHEN BLOWING

DUST)FOPERATIONISDUSTYALSOWEARADUSTMASK

7!2.).'

!LWAYSRELEASEALLPRESSUREDISCONNECTFROMPOWERSUP

PLYANDALLOWUNITTOCOOLTOTHETOUCHBEFORECLEANINGOR

MAKINGREPAIRSONTHEAIRCOMPRESSOR

'%.%2!,-!).4%.!.#%

(UMIDITYINTHEAIRCAUSESCONDENSATETOFORMINTHEAIR

TANK4HISCONDENSATESHOULDBEDRAINEDDAILYANDOR

EVERYHOURUSINGTHEINSTRUCTIONSFOUNDIN$RAININGTHE

4ANK

4HESAFETYVALVEAUTOMATICALLYRELEASESAIRIFTHEAIRRE

CEIVERPRESSUREEXCEEDSTHEPRESETMAXIMUM#HECKTHE

SAFETYVALVEBEFOREEACHUSEFOLLOWINGTHEINSTRUCTIONS

FOUNDIN#HECKINGTHE3AFETY6ALVE

)NSPECTTHETANKYEARLYFORRUSTPINHOLESOROTHERIMPER

FECTIONSTHATCOULDCAUSEITTOBECOMEUNSAFE

WARNING:

Do not at any time let brake fl uids, gasoline, petroleum-

based products, penetrating oils, etc., come in contact

with plastic parts. Chemical can damage, weaken or

destroy plastic which may result in serious personal

injury. Electric tools used on fi berglass material, wall-

board, spackling compounds, or plaster are subject

to accelerated wear and possible premature failure

because the fi berglass chips and grindings are highly

abrasive to bearings, brushes, commutators, etc.

Consequently, we do not recommend using this tool for

extended work on these type of materials. However, if

you do work with any of these materials, it is extremely

important to clean the tool using compressed air.

Summary of Contents for H2G3TK

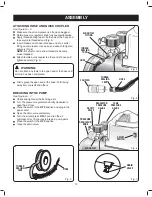

Page 13: ...13 Fig 9 Fig 8 THREAD SEALING TAPE...

Page 24: ...24 Portable Air Compressor Model No H2G3TK Replacement Parts List...

Page 25: ...25...

Page 27: ...27...

Page 28: ...OPERATOR S MANUAL H2G3TK 2 GALLON PORTABLE AIR COMPRESSOR CUSTOMER SERVICE 1 866 242 4298...

Page 41: ...13 Fig 9 Fig 8 CINTA SELLADORA ADAPTADOR DE INFLADO MANGUERA ESPIRAL...

Page 52: ...24 Compresor De Aire Port til Modelo N m H2G3TK Lista de piezas de repuesto...

Page 53: ...25...

Page 55: ...27...