Sirvase darnos la siguiente información:

-Número del modelo

-Número de Serie (de haberlo)

-Descripción y número del repuesto según la lista de repuestos

Puede escribirnos a:

The Campbell Group, Attn: Parts Department

100 Production Drive

Harrison, OH 45030

26 Sp

Pistola Pulverizadora Multiuso

1

Boquilla de aire (mezcla externa)

DH100400AV 1

2

Boquilla de aire (mezcla interna)

DH100500AV 1

3

Anillo DH100600AV 1

4

Sello de la boquilla de aire

DH100700AV 1

5

Boquilla, 14mm Hex

1

6

Empaque

(

)(

)

2

7

No se usa

8

Tuerca para sostener el

empaque, 8mm Hex

1

9

Cuerpo de la pistola

No se aplica

1

10

Anillo en O del control del patrón

(

)(

)

1

11

Ensamblaje de la aguja

del control del patrón

1

12

Anillo en O para la cámara

de la válvula

1

13

Tuerca para sostener el anillo en O

1

14

Anillo en O para la parte

del frente del vástago

1

15

Anillo en O para la parte

posterior del vástago

1

16

Vástago de la válvula de aire

DH101900AV 1

17

Ensamblaje de la aguja de flujo

1

18

Resorte para la válvula de aire

DH102100AV 1

19

Resorte para la aguja de flujo

1

20

Perilla para el control

del material

DH102300AV 1

21

Anillo en O para la parte

superior del envase

1

22

Parte superior del envase

DH102500AV 1

23

Tuerca, 14mm Hex

DH102600AV 1

24

Tubo de material

DH102701AV 1

25

Conexión de la entrada

de aire de 6,4mm (1/4”) NPS (M)

DH102800AV 1

26

Disco de la válvula

1

27

Resorte del sistema de presión/sifón

1

28

Ensamblaje de la válvula, 11mm Hex

(Válvula, conexión y perilla)

1

29

Anillo retenedor (anillo en E)

1

30

Pasador del gatillo

1

31

Gatillo

DH103200AV 1

32

Empaques para el envase

(paquete de 3)

DH420400AV 1

33

Envase de 1 litro

DH054001AV 1

JUEGOS DE REPUESTOS DISPONIBLES

PARA LA REPARACIÓN Y MANTENIMIENTO

Empaques

DH530100AV

Control de flujo

DH530200AV

Control de patrón

DH530400AV

Válvula de control de presión/sifón

DH530300AV

No. de

Número del

Ref.

Descripción

Repuesto

Ctd

No. de

Número del

Ref.

Descripción

Repuesto

Ctd

Lista De Repuestos

MATERIAL & PATTERN

ADJUSTMENTS

Always test spray

gun on scrap

material to avoid damage to workpiece.

1. Adjust air pressure to the spray gun

according to the recommendations

supplied with the spray material.

This air pressure usually falls

between 30-50 PSI.

2. Set pattern size to desired shape. For

full pattern, open pattern control

knob by turning counterclockwise.

For a round pattern, turn pattern

control knob clockwise (See Figure 4).

3. Turn fluid control knob fully clockwise

until closed.

4. With gun 8” away from surface,

trigger a short, one second burst while

turning fluid control knob

counterclockwise. Observe the spray

pattern on the target and adjust the

fluid control knob until the desired

pattern (atomization) is obtained (See

Figure 5).

NOTICE

Preparation

MATERIAL PREPARATION

1. Before using desired material in the

spray gun, spray a compatible

thinner or solvent through the gun

to remove any contaminants and

residue.

2. Thoroughly mix the material in

accordance with the manufacturer’s

instructions. If necessary, thin per

paint manufacturer’s instructions.

Strain material through a paint

strainer. Test the consistency of the

material by making a few strokes on

a cardboard target. Be sure the spray

material is clean and free from lumps.

3. Fill the canister about 3/4 full with

material and start the air

compressor. Be sure the hose(s) is

long enough to allow a full

movement of the gun across the

surface to be painted.

4. Be sure that the air pressure

regulator is set for the proper

operation of the gun. Refer to the

specifications section. Air pressure

should be checked at the spray gun

inlet with the trigger pulled.

5. Set up a piece of cardboard or other

scrap material to use as a target and

adjust for best spray pattern.

3

Set Up (Continued)

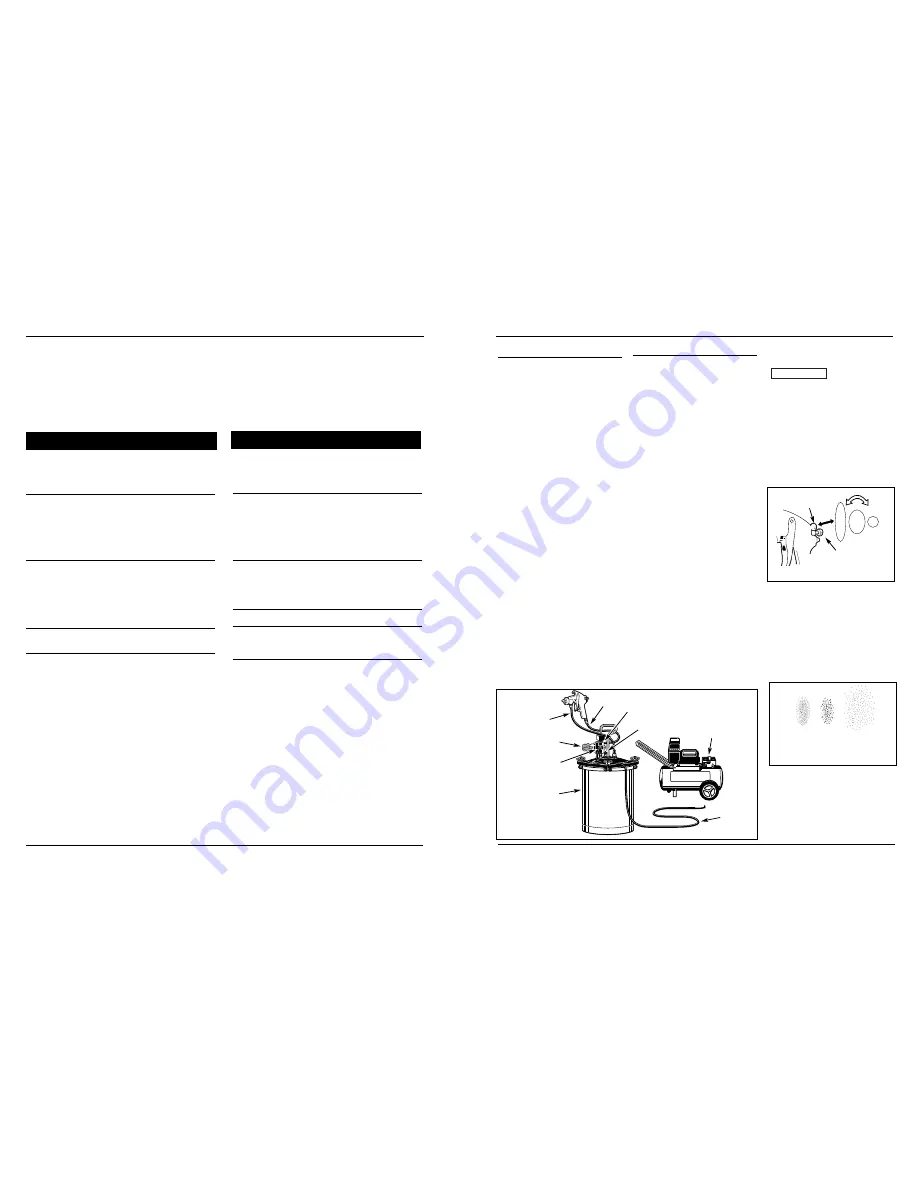

USING A PRESSURIZED PAINT TANK

This model is readily adaptable for use

with a pressurized paint tank. This

allows continuous spraying of large

quantities of paint without stopping. It

also allows the gun to be used while

being held in ANY position without

spilling paint.

The proper connections to make when

using a pressurized paint tank are as

illustrated in Figure 3. Refer to the

instructions supplied with the paint

tank for connections and usage.

DO

NOT USE A PAINT TANK WITHOUT

READING THOSE INSTRUCTIONS

.

Prepare the spray gun for use with the

paint tank as follows:

1. Remove the canister.

2. Unscrew the material tube.

3. After the tube is removed, locate the

brass locknut and remove the nut

using a 14 mm hex socket.

4. Remove the canister top and gasket.

5. Attach the material hose from the

paint tank to the spray gun.

6. Pressure/siphon valve knob must be

tightened clockwise (S direction)

when using a pressurized paint tank

connected as shown in Figure 3. This

will prevent pressurized air from

escaping out of the canister pressure

valve port when the canister is not

used.

Figure 3 - Paint Tank

Connections

Paint Tank Regulator

Safety Valve

Air Hose

Paint Tank

Material Hose

Air Hose

High - Out To Spray Gun

High - In from

compressor

Air Source

Regulator

Figure 4 - Pattern Size

Pattern

Control Knob

Fluid Control

Knob

Correct

Paint Too

Thick

Paint

Too Thin

Figure 5 - Pattern Consistency

(Atomization)