Manuel de Instrucciones y Lista de Piezas

HDS650

30 Sp

3

Types of Spray Gun

Set-Ups

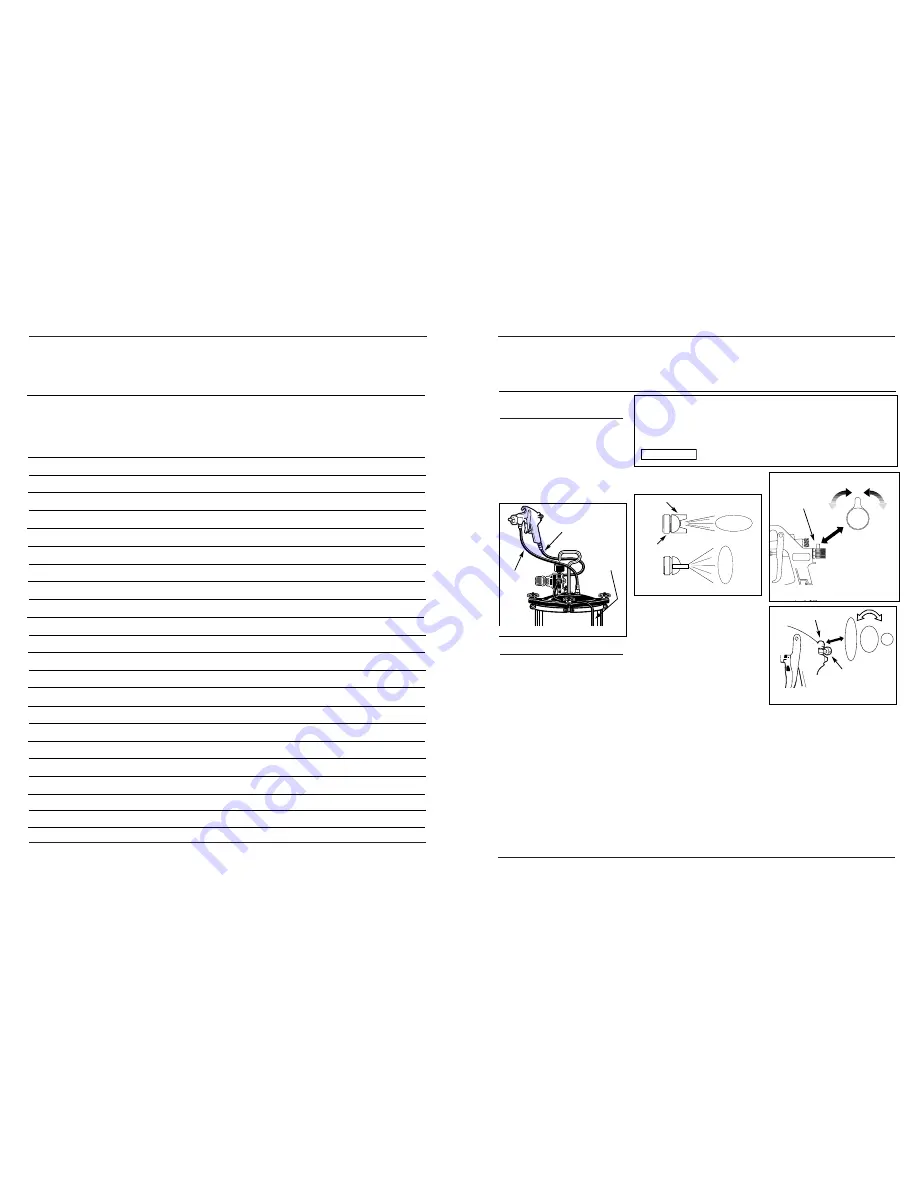

PRESSURE FEED TANK SET-UP

This method is the same as the pressure

feed cup set-up except that the gun can

be oriented in any position independent

of the tank (See Figure 3). This method

is useful for medium production or

large scale spraying applications.

Preparation

1. Thoroughly mix the paint in accor-

dance with the manufacturer’s

instructions, adding thinner where

necessary. Most materials will spray

readily if thinned properly. Strain

material through cheese cloth or a

paint strainer. Test the consistency of

the material by making a few strokes

on a cardboard target. If material still

appears too thick, add a small

amount of thinner. THIN WITH CARE!

2. Fill the canister about 3/4 full and

start the air compressor.

3. Set up a piece of cardboard or other

scrap material to use as a target and

adjust for best spray pattern.

FAN DIRECTION

The direction of the fan (horizontal or

vertical) can be changed by loosening

the lock ring and turning the air cap 90

degrees (See Figure 4). Hand tighten

lock ring after adjustment.

PATTERN ADJUSTMENT

SIPHON FEED

1. Adjust air pressure to the spray gun

according to the recommendations

supplied with the spray material. This

air pressure usually falls between 40 -

60 PSI. Adjust air pressure with the

trigger pulled and air control knob

(if applicable) fully open. If reduced

air pressure is desired for some areas

of the spray job, use air control knob

to reduce pressure as necessary (See

Figure 5).

2. Set pattern size to desired shape. For

full pattern, open pattern control

knob by turning counterclockwise.

For a round pattern, turn pattern

control knob clockwise (See Figure 6).

3. Turn fluid control knob fully clock-

wise until closed (See Figure 6).

4. Trigger a short burst while turning

fluid control knob counterclockwise.

Observe the spray pattern on the tar-

get and adjust the fluid control knob

until the desired pattern (atomiza-

tion) is obtained (See Figure 7).

If the spray is too fine (excessive over-

spray), caused by too much air for the

amount of paint being sprayed, reduce

the air pressure or open the fluid con-

trol to spray more material.

If the spray is too coarse (spitting globs),

reduce the amount of material with the

fluid control knob or thin the paint.

PRESSURE FEED SET-UP

1. Adjust air pressure to the spray gun

according to the recommendations

supplied with the spray material. This

WATER/OIL IN COMPRESSED AIR

All compressor pumps discharge some condensed water, oil or contaminates with

the compressed air.

IMPORTANT:

This condensation will cause “fish eyes” to appear in the paint

job. Install appropriate water/oil removal equipment and controls as necessary

for the intended application.

Failure to install appropriate water/oil removal equipment

may result in damage to machinery or workpiece.

NOTICE

Figure 4

Horizontal Fan

Vertical Fan

Air Cap

Lock Ring

Operating Instructions and Parts Manual

HDS650

PEEDAIRE

Increase

Air Flow

Decrease

Air Flow

Figure 5 - Air Adjustment on

Spray Gun

Air Control

Knob

Figure 6 - Pattern Size

Pattern control knob

Fluid control

knob

Figure 3 - Pressure Feed Tank Set-up

Air to Spray Gun

Filtered,

Regulated

Air Source

Pressure Tank

Fluid

Hose

Notas

Pistola de Pulverización con

Alimentación por Sifón