5

Operating Instructions and Parts Manual

Gravity Feed Spray Gun

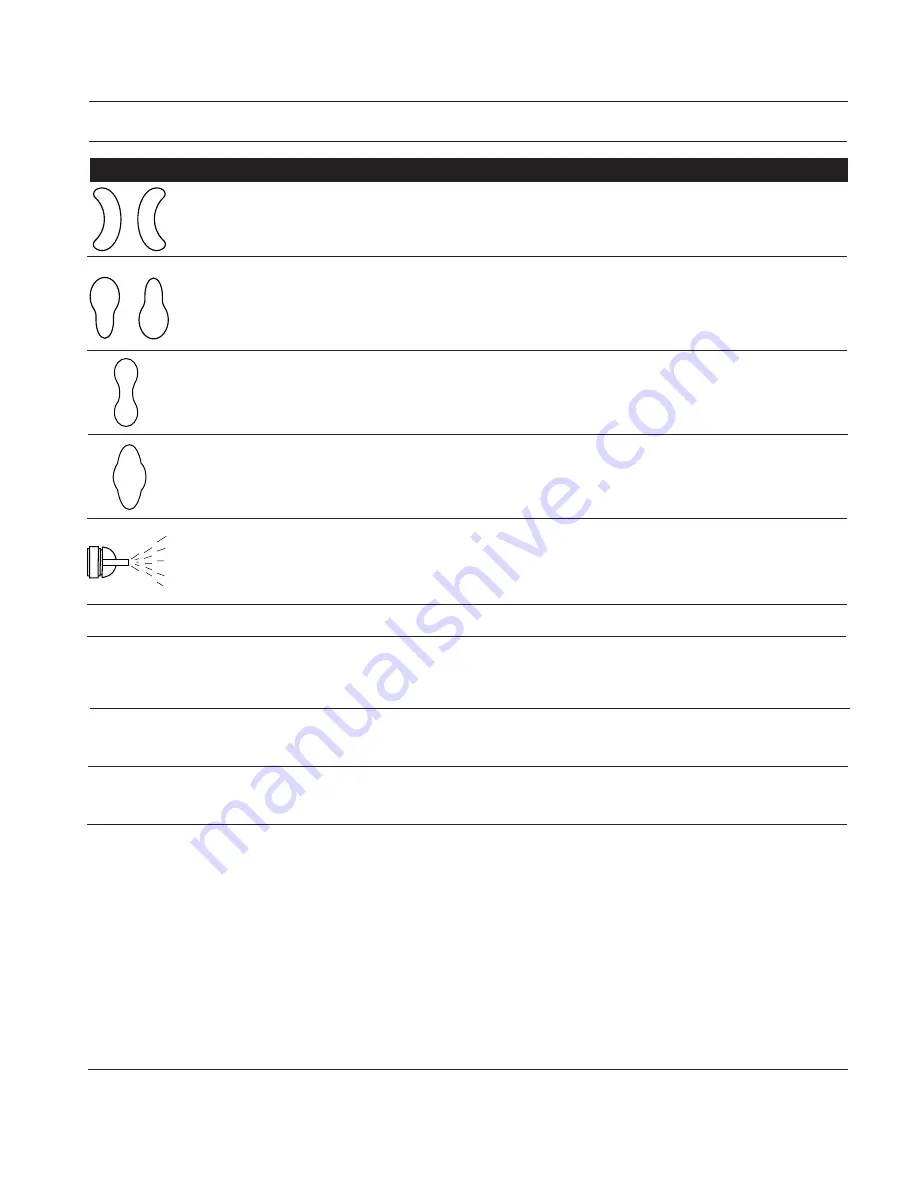

Right or left

heavy spray

pattern

Top or bot-

tom heavy

spray pat-

tern

Split spray

pattern

Center

heavy spray

pattern

Sputtering

spray

Fluid leaking from pack-

ing nut

Air leaking from air cap

without pulling trigger

Fluid leaking from fluid tip

of pressure feed spray gun

Excessive overspray

Will not spray

Troubleshooting Chart

Symptom Possible

Cause(s)

Corrective

Action

1.

Holes in left or right side of the air

cap are plugged

2.

Dirt on left or right side of fluid tip

1.

Dried material at top or bottom of

fluid tip

2.

Loose air cap or dirty seat

3. Air

cap

plugged

1.

Fan pattern open too far

2.

Fluid turned in too far

3.

Atomization air too high

1.

Fan adjustment partially closed

2. Material

too

thick

3.

Atomization pressure too low

1.

Material level too low

2.

Container tipped too far

3.

Loose fluid inlet connection

4.

Loose or damaged fluid tip/seat

5.

Dry or loose fluid needle packing nut

6. Air

vent

clogged

1. Packing

nut

loose

2.

Packing worn or dry

1.

Sticking air valve stem

2.

Contaminate on air valve or seat

3.

Worn or damaged air valve or seat

4.

Broken air valve spring

5. Bent

valve

stem

1.

Packing nut too tight

2.

Fluid tip worn or damaged

3.

Foreign matter on tip

4.

Fluid needle spring broken

1.

Too high atomization pressure

2.

Too far from work surface

3.

Improper stroking (arcing, gun

motion too fast)

1.

No pressure at gun

2.

Fluid control not open enough

3. Fluid

too

heavy

1.

Clean. Use only non-metallic point

2. Clean

1. Clean

2. Clean

and

tighten

3.

Clean. Use only non-metallic point

1.

Partially close the pattern adjustment

2. Increase

fluid

3.

Reduce atomization air pressure

1.

Open fan pattern adjustment

2.

Thin to proper viscosity

3. Increase

atomization

pressure

1. Refill

2. Hold

more

upright

3. Tighten

4. Adjust

or

replace

5.

Lubricate and or tighten

6. Clear

vent

hole

1.

Tighten, but do not restrict needle

2.

Replace or lubricate (non-silicone oil)

1. Lubricate

2. Clean

3. Replace

4. Replace

5. Replace

1. Adjust

2.

Replace tip and/or needle

3. Clean

4. Replace

1. Reduce

pressure

2.

Adjust to proper distance

3.

Move at moderate pace, parallel to surface

1. Check

air

lines

2. Open

fluid

control

3.

Thin fluid or change to pressure feed system