20

Maintenance (continued)

4

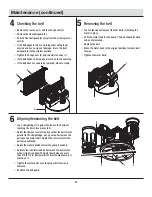

Checking the belt

□

Remove the four caps (1) and four fl ange nuts (2).

□

Remove the front beltguard (3).

□

Pull the front beltguard (3) away from the air compressor

unit (A).

□

If the belt appears to be in working order with proper

tension and has no signs of damage, return the front

beltguard (3) to the original position.

□

Tighten the fl ange nuts (2) and reinstall the caps (1).

□

If the belt needs to be replaced, move on to the next step.

□

If the belt does not need to be replaced, move to step 6.

5

Removing the belt

□

Loosen (but do not remove) the four bolts (1) holding the

motor in place.

□

Shift the motor towards the pump. The belt should be slack

and easily removed.

□

Replace the belt.

□

Move the motor back to the original position to create belt

tension.

□

Tighten the motor bolts.

6

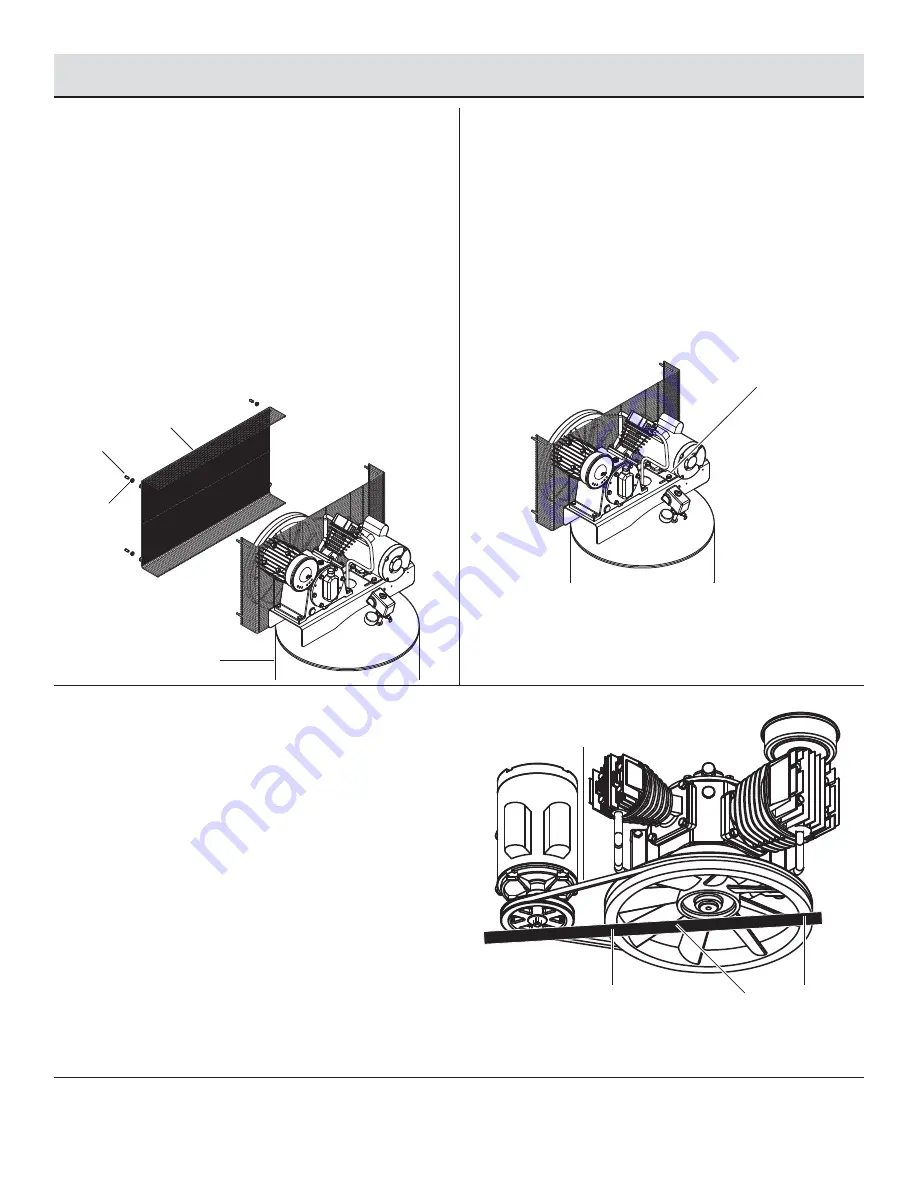

Aligning / tensioning the belt

□

Lay a straightedge (1) against the face of the fl ywheel

touching the rim at two places (2,3).

□

Adjust the flywheel or motor pulley so that the belt (4) runs

parallel to the straightedge. Use a gear puller to move the

pulley on the motor shaft. Tighten the setscrew after the

pulley is positioned.

□

Adjust the motor’s distance from the pump if needed.

□

Belt tension is determined by how much the belt moves

when weight is applied. The belt should move no more

than 3/8 to 1/2 in. downward if normal thumb pressure is

placed on it.

□

Tighten the motor bolts once the proper belt tension is

achieved.

□

Reattach the belt guard.

1

2

4

3

1

3

2

A

1