1

2

b

2

1

a

Getting Ready to Sew

– 13

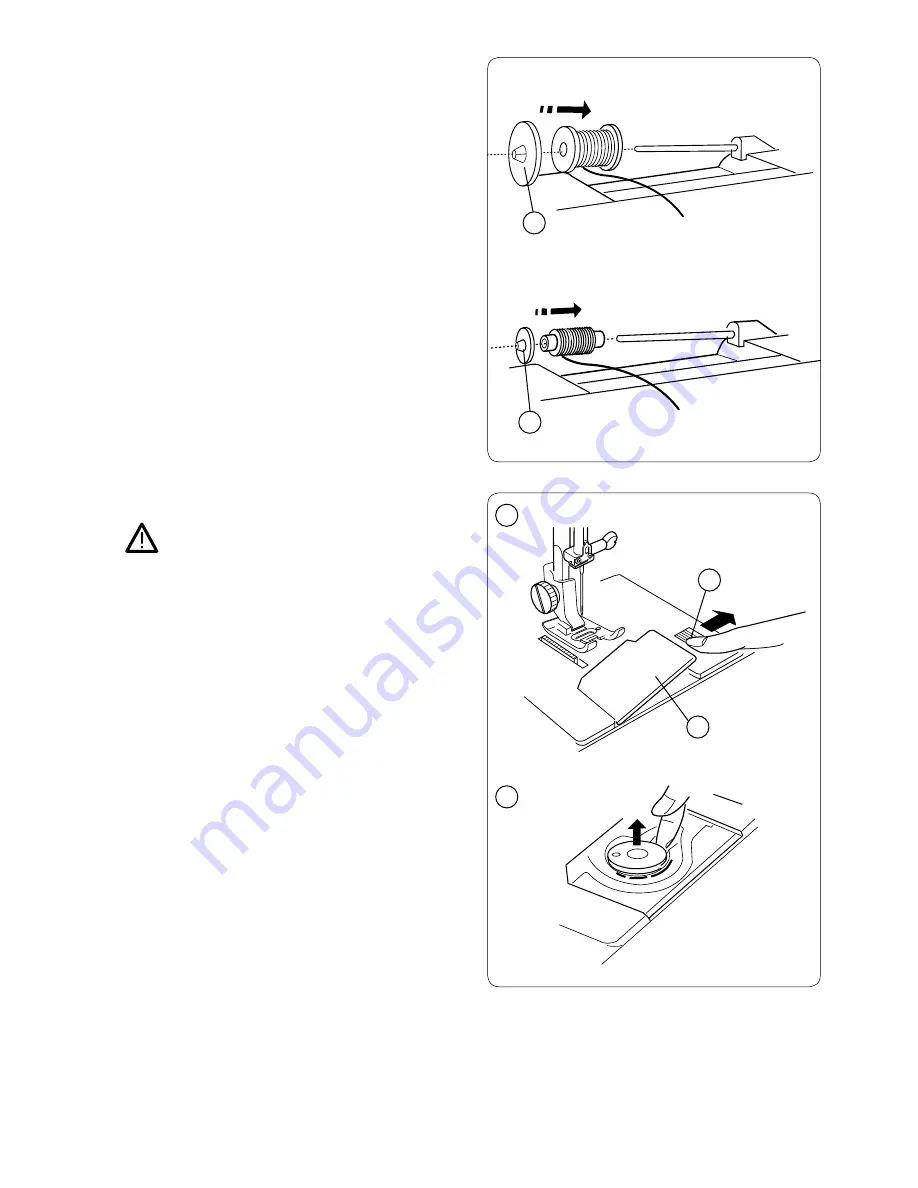

PLaCinG the thread sPooL

on the sPooL Pin

Place the thread spool on the spool pin

with the thread coming off as illustrated.

With large thread spools, the large

holder is placed in front of the thread. If

you use narrow thread spools, the small

holder is placed in front of the thread.

1.

Large spool holder

2.

Small spool holder

reMovinG the BoBBin

Turn off the power switch.

1.

Push the bobbin cover release

button to the right and remove the

cover.

a.

Release button

b.

Bobbin cover plate

2.

Lift out the bobbin.