2

B

Functions and InfoDisplay

24

How to Use the Sewing Advisor

Your fabric selection stays active until

another fabric is selected, and the last fabric

selected is always retained in the memory -

even when the machine is turned off.

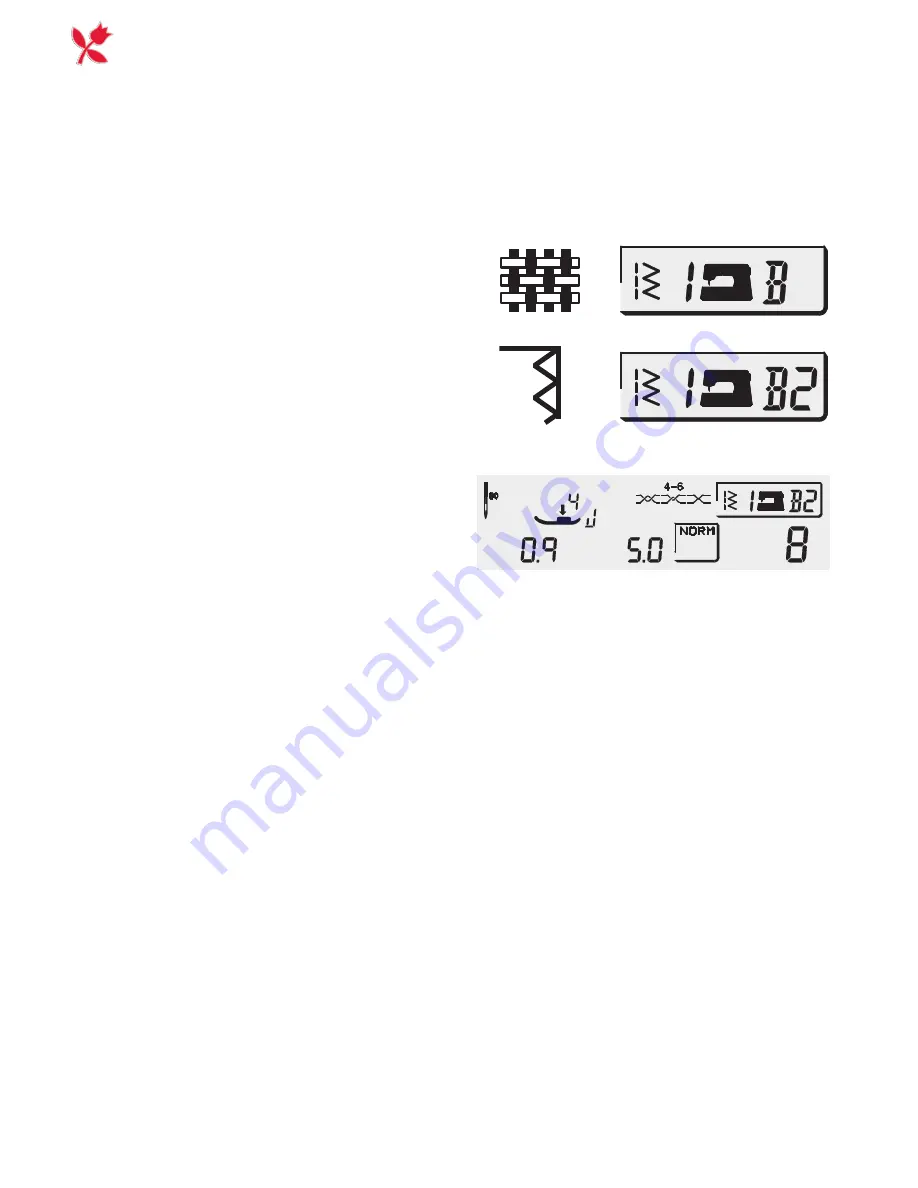

When touching a fabric button, the letter

corresponding to that fabric appears in the

Overview Window indicating the selection.

After you have selected the desired fabric,

select the technique of your choice. You

can then view the stitch number and all the

default recommendations.

The settings made on the

SEWING

ADVI

-

SOR

are always visible in the Overview

Window. The letter indicates the fabric and

the number the technique. If another stitch

than the one recommended by the

SEWING

ADVISOR

is selected, the selected fabric

remains.

Summary of Contents for Platinum 715

Page 1: ...K E E P I N G T H E W O R L D S E W I N G User s Guide ...

Page 19: ...FUNCTIONS AND INFODISPLAY ...

Page 35: ...SEWING ...

Page 51: ...CARE OFYOUR PLATINUM ...

Page 58: ......