13

OPERATION

CAUTION

• DO NOT operate mower with grass

catcher partially installed.

• Disengage blades and stop engine

before leaving mower seat to

empty containers, unclogging

chutes, etc.

• Close cover before starting.

• Disengage mower blades when

crossing driveways or gravel

surfaces and other areas where

thrown objects could be a hazard.

• DO NOT attempt to vacuum cans

or other potentially hazardous

projectiles.

STORAGE

When grass catcher is to be stored for a period of

time, clean it thoroughly, remove all dirt, grass, leaves,

etc. Store in a clean, dry place.

CAUTION

Do not leave grass in bagger

containers. Empty containers after

each use and before storing. Failure

to do so may result in spontaneous

combustion which could develop into

a fire.

CAUTION

Grass catcher components are subject

to wear, damage and deterioration,

which could expose moving parts or

allow objects to be thrown. Frequently

check components and replace with

manufacturer’s recommended parts,

when necessary.

Summary of Contents for 115 149727 R01

Page 1: ...Blower Kit 44 Collection System 966004401 Operator and Parts Manual ...

Page 2: ... 2009 HTC All Rights Reserved Beatrice NE Printed in U S A ...

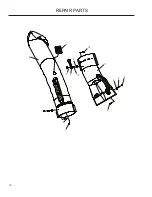

Page 16: ...16 REPAIR PARTS 1 3 7 4 5 8 18 11 14 15 16 10 12 6 2 17 5 17 19 9 13 17 ...

Page 18: ...18 6 5 4 4 3 3 1 9 2 12 10 7 8 11 REPAIR PARTS ...

Page 22: ......

Page 23: ......

Page 24: ...P N 115 149727 R01 05 09 09 ...