MAINTENANCE

English

–

33

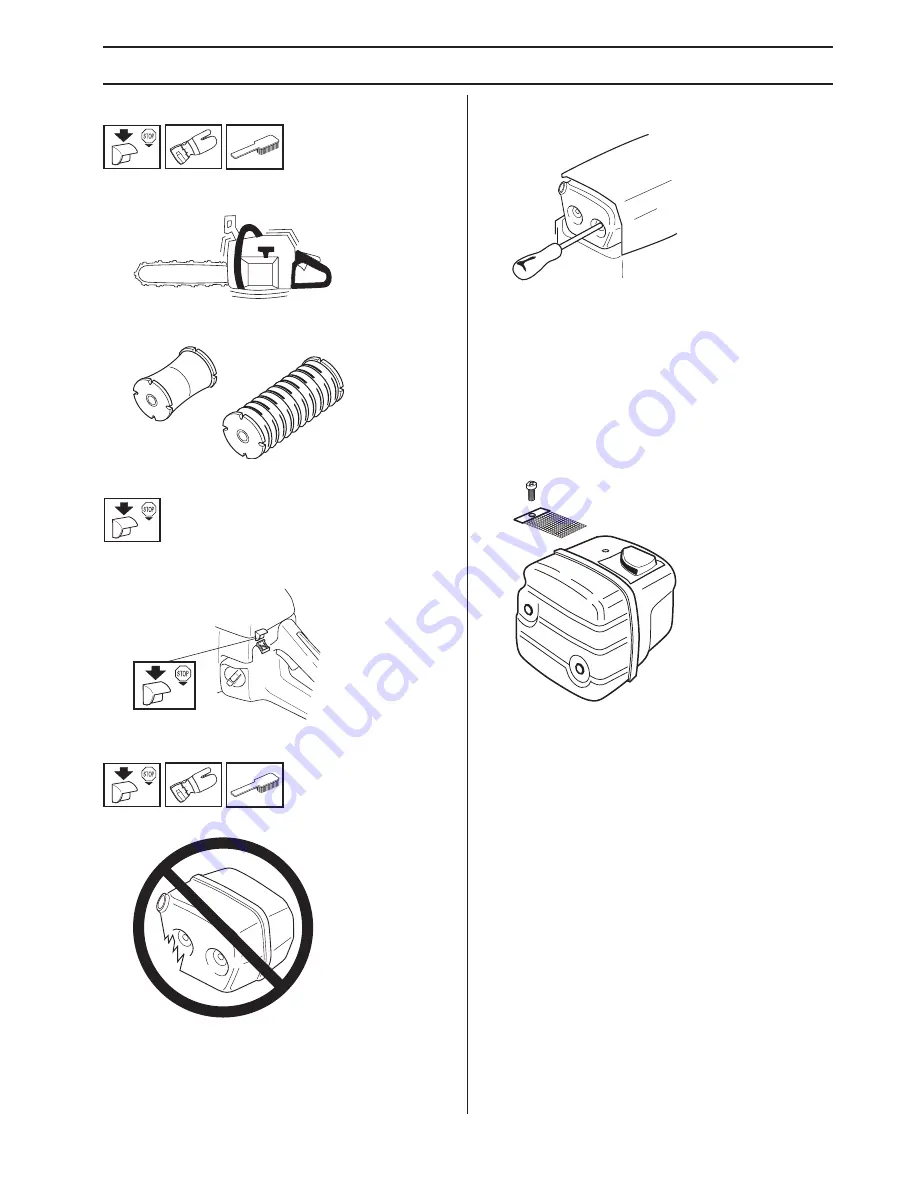

Vibration damping system

Regularly check the vibration damping units for cracks or

deformation.

Make sure the vibration damping units are securely

attached to the engine unit and handle unit.

Stop switch

Start the engine and make sure the engine stops when

you move the stop switch to the stop setting.

Muffler

Never use a machine that has a faulty muffler.

Regularly check that the muffler is securely attached to

the machine.

Some mufflers are equipped with a special spark arrestor

screen. If your machine has this type of muffler, you

should clean the screen at least once a week. This is best

done with a wire brush. A blocked screen will cause the

engine to overheat and may lead to serious damage.

Note! The screen must be replaced if it is damaged. If the

screen is blocked the machine will overheat and this will

cause damage to the cylinder and piston. Never use a

machine with a muffler that is in poor condition.

Never

use a muffler if the spark arrestor screen is missing

or defective.

The muffler is designed to reduce the noise level and to

direct the exhaust gases away from the operator. The

exhaust gases are hot and can contain sparks, which may

cause fire if directed against dry and combustible

material.

A muffler equipped with a catalytic converter significantly

reduces the amount of hydrocarbons (HC), nitrogen

oxides (NO) and aldehydes in the exhaust fumes. Carbon

monoxide (CO), which is poisonous and odorless, is not

however reduced! Consequently, never work in an

enclosed or badly ventilated area. Good air circulation

should always prevail when working in snowy hollows,

ravines or in confined conditions.