ASSEMBLY

English

–

17

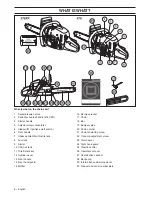

Fitting the bar and chain

Check that the chain brake is in disengaged position by

moving the front hand guard towards the front handle.

Remove the bar nuts and remove the clutch cover (chain

brake). Take off the transportation ring (A).

Fit the bar over the bar bolts. Place the bar in its rearmost

position. Place the chain over the drive sprocket locate it

in the groove on the bar. Begin on the top edge of the bar.

Make sure that the edges of the cutting links are facing

forward on the top edge of the bar.

Fit the clutch cover and locate the chain adjuster pin in the

hole in the bar. Check that the drive links of the chain fit

correctly over the drive sprocket and that the chain is

correctly located in the groove in the bar. Tighten the bar

nuts finger tight.

Tension the chain by turning the chain tensioning screw

clockwise using the combination spanner.

The chain is correctly tensioned when it does not sag from

the underside of the bar, but can still be turned easily by

hand. Hold up the bar tip and tighten the bar nuts with the

combination spanner.

When fitting a new chain, the chain tension has to be

checked frequently until the chain is run-in. Check the

chain tension regularly. A correctly tensioned chain

ensures good cutting performance and long life.

Note: If clutch cover is difficult to remove, replace bar

nuts, engage brake and rerelease (an audible click will be

heard if released properly).

!

WARNING! Always wear gloves, when

working with the chain.