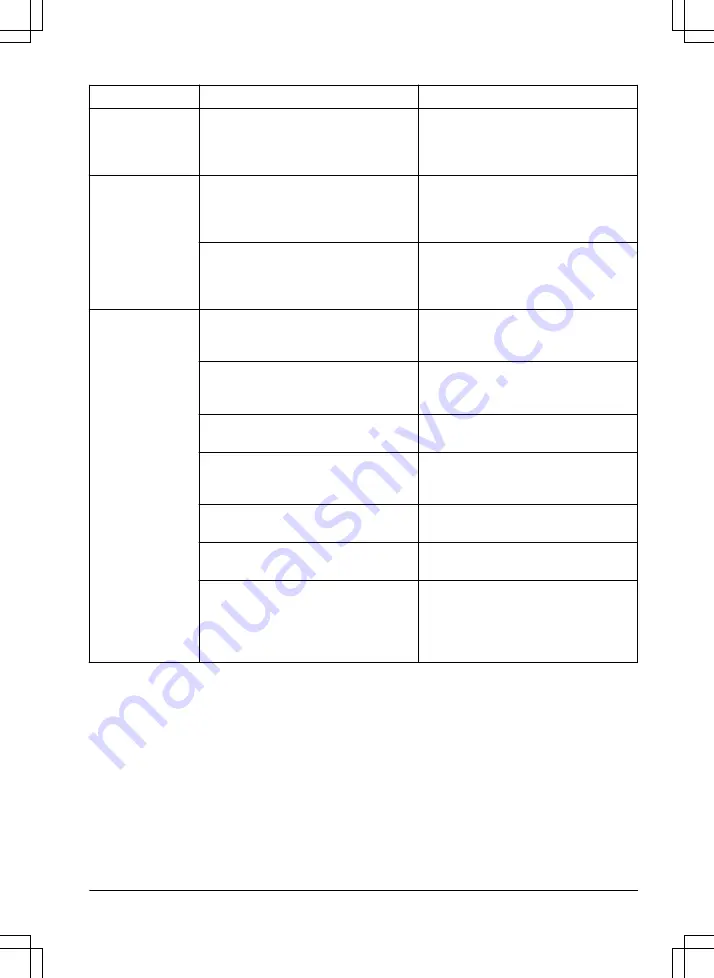

Symptoms

Cause

Action

Both the mowing

and charging times

are shorter than

usual.

The battery is spent.

on page 31.

The product is

parked for hours in

the charging sta-

tion.

The product has an inbuilt standby peri-

od according to the Standby time table.

Refer to

21.

No action.

The STOP button has been activated.

Open the hatch, enter the PIN code

and confirm with the OK button. Press

the Start button and then close the

hatch.

Uneven mowing

results.

The product works too few hours per

day.

Increase the mowing time. Refer to

calculate the schedule setting on page

21.

The shape of the work area requires

the use of

Area 1-3 for the product to

find its way to all remote areas.

Use

Area 1-3 to steer the product to a

remote area. Refer to

The

How often? setting is incorrect in

relation to the layout of the work area.

Check that the correct

How often? val-

ue is selected.

Work area too large.

Try limiting the work area or extending

schedule on page 21.

Dull blades.

Replace all the blades. Refer to

Long grass in relation to the set cutting

height.

Increase the cutting height and then

successively lower it.

Accumulation of grass by the blade

disc or around the motor shaft.

Check that the blade disc rotates freely

and easily. If not, screw off the blade

disc and remove grass and foreign ob-

jects. Refer to

page 29.

6.6 Find breaks in the loop wire

Breaks in the loop wire are usually the result of

unintentional physical damage to the wire such

as when gardening with a shovel. In countries

with ground frost, also sharp stones that move in

the ground can damage the wire. Breaks can

also occur due to the wire being stretched

excessively during installation.

Mowing the grass too low right after the

installation can damage wire insulation. Damage

to the insulation may not cause disruptions until

several weeks or months later. To avoid this,

always select the maximum cutting height the

first weeks after installation and then lower the

height one step at a time every second week until

the desired cutting height has been reached.

A defective splicing of the loop wire can also lead

to disruptions several weeks after the splice was

done. A faulty splice can, for example, be the

result of the original coupler not being pressed

together hard enough with a pair of pliers, or that

a coupler of lower quality than the original

coupler has been used. Please first check all

known splices before further troubleshooting is

done.

982 - 001 - 12.12.2018

Troubleshooting - 41