6

ASSEMBLY / PRE-OPERATION

Read these instructions and this manual in its entirety before you attempt to assemble or operate your new

snow thrower. Reading the entire manual will familiarize you with the unit, which will assist you in assembly,

operation and maintenance of the product.

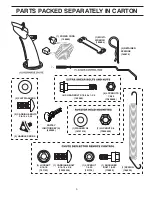

Your new snow thrower has been as sem bled at the factory with the ex cep tion of those parts left unassembled for shipping

purposes. All parts such as nuts, washers, bolts, etc., necessary to com plete the as sem bly have been placed in the parts

bag. To ensure safe and proper operation of your snow thrower, all parts and hard ware you assemble must be tightened

se cure ly. Use the correct tools as nec es sary to ensure proper tightness.

REMOVE SNOW THROWER FROM CAR TON

1. Remove all accessible loose parts and parts boxes

from carton.

2. Cut down all four corners of carton and lay panels flat.

3. Remove the two (2) screws securing the auger housing

to the pallet.

4. Remove all packing materials ex cept plastic tie holding

speed control rod to lower handle.

5. Remove the two (2) plastic ties securing the upper

handle to the pallet.

6. Remove snow thrower from carton and check carton

thor ough ly for ad di tion al loose parts.

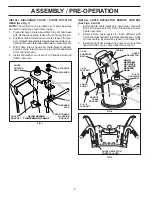

HOW TO SET UP YOUR SNOW THROWER

TOOL BOX (See Fig. 10)

A toolbox is provided on your snow thrower. The toolbox is

located on top of the belt cover. Store the extra shear bolts,

nuts and multi-wrench provided in parts bag in the toolbox.

NOTE:

The multi-wrench may be used for assembly of the

chute rotator head to snow thrower and making ad just ments

to the skid plates.

UNFOLD UPPER HANDLE

1. Raise upper handle to the operating position and

tight en handle knobs securely. Additional carriage

bolts, washers and handle knobs are in bag of parts.

Use to secure upper handle to lower handle. Install

in lower holes in handles.

INSTALL SPEED CONTROL ROD (See Figs. 1 and 2)

1. Remove plastic tie securing rod to lower handle.

2. Insert rod into speed control bracket and secure with

retainer spring.

SPEED

CONTROL

ROD

HANDLE

KNOB

LOWER

HANDLE

PLASTIC TIE

UPPER

HANDLE

FIG. 1

SPEED CON TROL ROD

SPEED

CONTROL

BRACKET

SPEED

CONTROL

LEVER

FIG. 2

RETAINER

SPRING

Summary of Contents for 1827EXLT

Page 27: ...27 SERVICE NOTES ...

Page 28: ...08 01 2011 SR ...