English – 35

TECHNICAL DATA

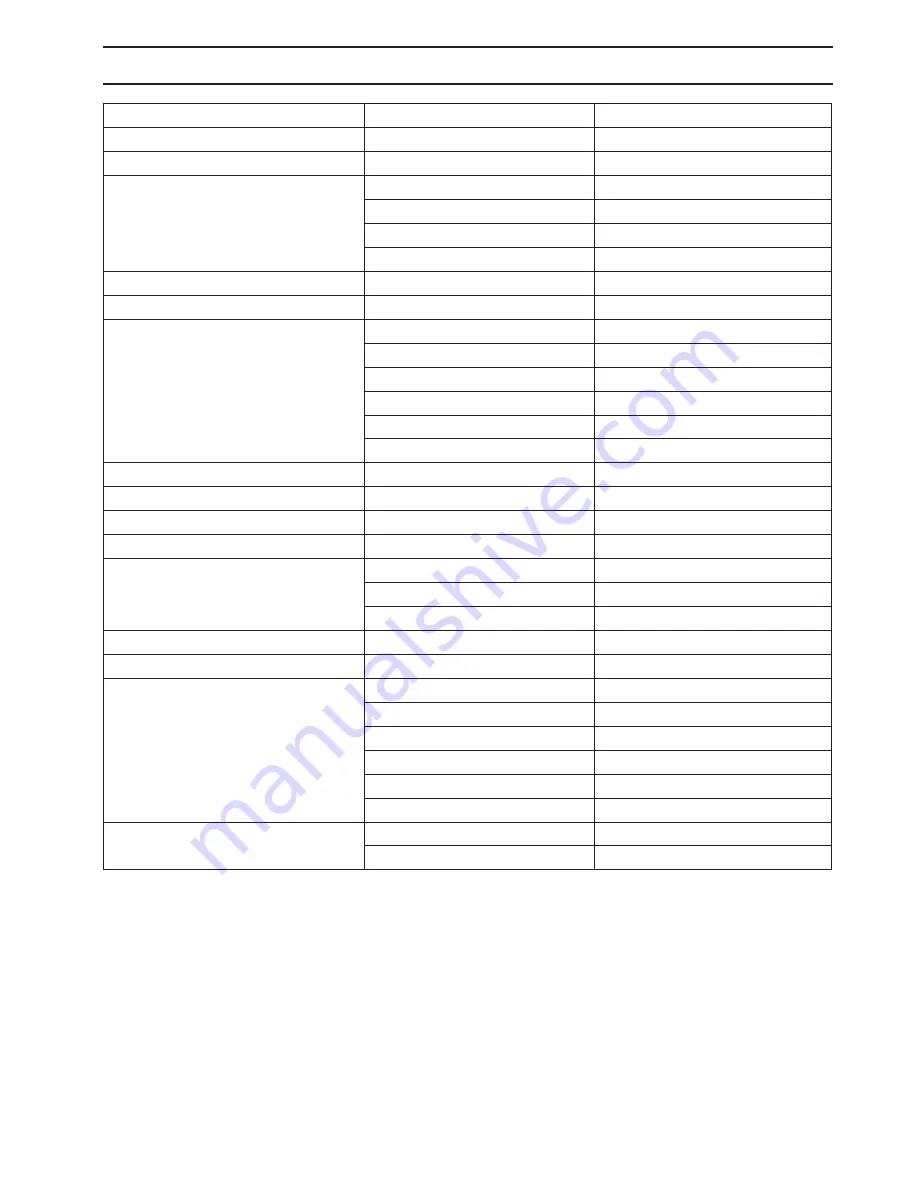

Approved accessories 232R

Type

Cutting attachment guard, Art. no.

Centre hole in blades/cutters, Ø 25,4 mm

Arbor shaft thread M10

Grass blade/grass cutter

Grass 255-4 (Ø 255 4 teeth)

503 74 40-01

Grass 255-8 (Ø 255 8 teeth)

503 74 40-01

Multi 255-3 (Ø 255 3 teeth)

503 74 40-01

Multi 275-4 (Ø 275 4 teeth)

503 74 40-01

Saw blade

Maxi X 200-26 (Ø 200 26 teeth)

503 77 39-01

Plastic blades

Tricut Ø 300 mm

503 74 50-01

Trimmer head

S35

503 74 50-04

T35

503 74 50-04

Trimmy Hit

503 74 50-04

Trimmy Hit Pro

503 74 50-04

Trimmy Fix

503 74 50-04

Superauto II

503 74 50-04

Support cup

Fixed

-

Approved accessories 235R, 235FR

Type

Cutting attachment guard, Art. no.

Centre hole in blades/cutters, Ø 25,4 mm

Output shaft thread M12

Grass blade/grass cutter

Multi 255-3 (Ø 255 3 teeth)

537 33 16-01

Multi 275-4 (Ø 275 4 teeth)

537 33 16-01

Multi 300-3 (Ø 300 3 teeth)

537 33 16-01

Saw blade

Scarlet 200-22 (Ø 200 22 teeth)

537 38 77-01

Plastic blades

Tricut Ø 300 mm

537 33 16-01 / 537 34 94-01

Trimmer head

Trimmy S II

537 33 16-01 / 537 34 94-01

T35, T35x

537 33 16-01 / 537 34 94-01

T45x

537 33 16-01 / 537 34 94-01

S35

537 33 16-01 / 537 34 94-01

F35

537 33 16-01 / 537 34 94-01

Auto 55

537 33 16-01 / 537 34 94-01

Support cup

Fixed

-

With ball bearing

-

Summary of Contents for 227R

Page 39: ......

Page 40: ...T35 T35x Clic 1 2 3 5 6 7 9 8 5 m 28 4 8 4 3 m 14 2 4 2 7 mm 095 106 10 cm 4 6 15 cm ...

Page 44: ......

Page 45: ... Clic 1 2 3 5 6 7 10 11 8 5 m 28 4 8 4 2 m 14 2 4 2 7 mm 095 106 10 cm 4 6 15 cm S35 ...

Page 46: ...1 2 4 3 2 4 2 7 mm 095 106 4 25 m 14 4 25 m 14 B 6 15 cm A 6 15 cm S35 5 ...

Page 47: ... Clic 1 2 3 5 6 7 9 10 m 32 4 8 4 3 m 14 2 7 3 3 mm 106 13 10 cm 4 6 15 cm T45 T45x ...

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......