3

26

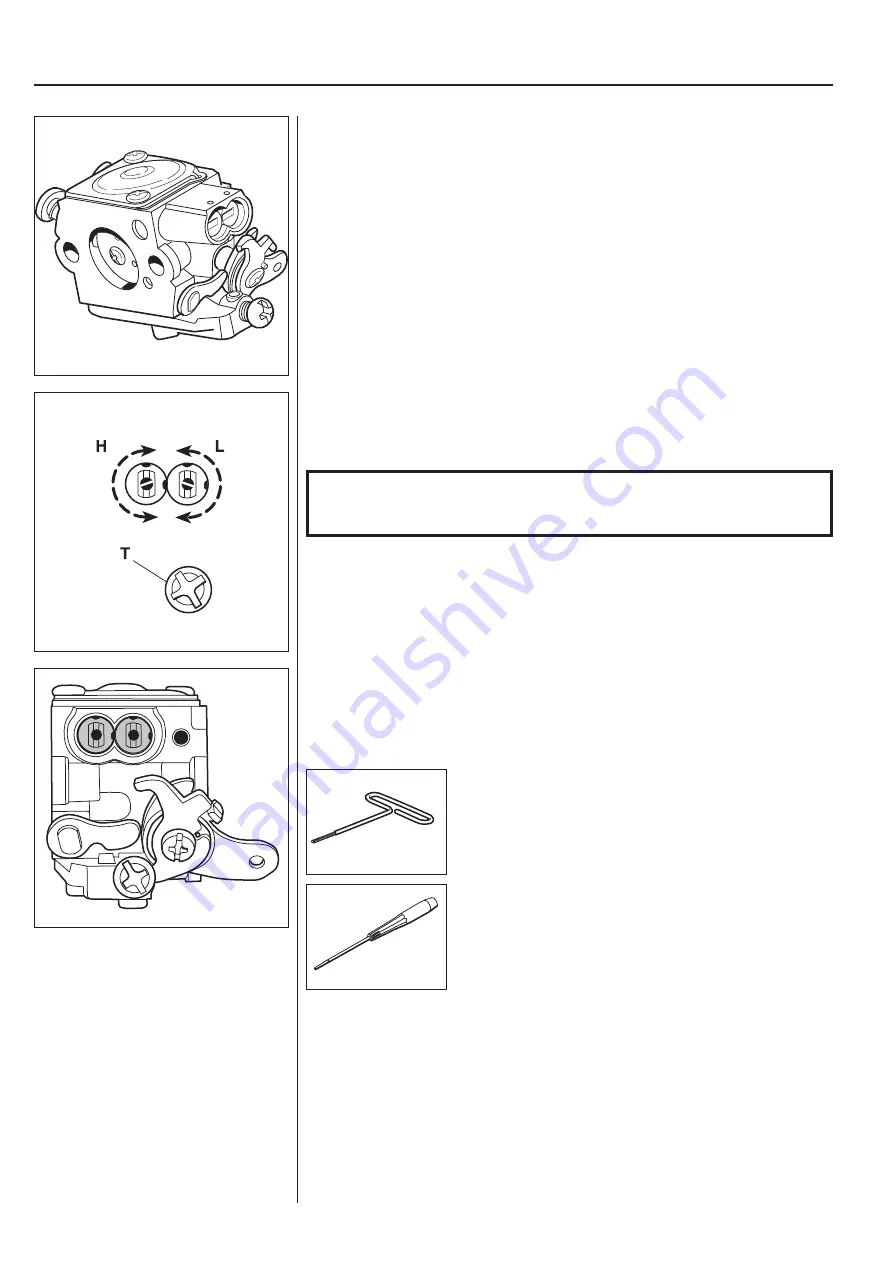

H

L

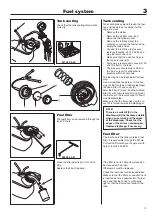

531 00 48-63

540 06 82-01

Fuel system

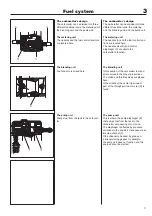

Fine adjustment after running-in

After the running-in period it may be necessary to

fi

ne adjust the carburettor nozzles,

usually to get a leaner fuel/air mix.

The basic factory setting is somewhat “richer” than the optimal setting (fast idle speed is

600 - 800 rpm below recommended maximum revs) and shall be maintained for the

fi

rst

hours of engine operation.

NOTE!

Warm up the engine 4 minutes at 9,500 - 10,000 rpm before beginning

carburettor adjustment.

To carry out a correct adjustment, the engine must be under load during adjustment.

This is achieved by

fi

tting trimmer T35 with speci

fi

ed length and diameter on the trimmer

thread (see below).

The combiguard or trim guard must be

fi

tted when adjusting the H-needle.

•

At full throttle, the H-needle shall have a setting so that the engine is almost

splutters.

•

Since the ignition system is limited in terms of rpm, the pre-programmed fast idle

speed (12,500 rpm) cannot be exceeded even if the H-needle is screwed inwards.

The risk in this case is still that the engine breaks down as a result of a too lean

fuel/air mix.

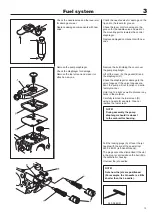

Limited adjustments of the jet needles can be made with a

screwdriver without having to dismantle the stop plugs. The

needles can be turned max. a quarter turn in either direction.

If the carburettor cannot be adjusted suf

fi

ciently, the jet nee-

dles can be released if the stop plugs are pulled out until they

are level with the carburettor housing or removed completely

using the tool 540 06 82-01 (left-hand threads).

Use the special screwdriver 531 00 48-63, which is thin

enough to be stuck into the hole in the stop plug and the

groove in the jet needle.

Push in the stop plugs in the carburettor housing after com-

pleted adjustment. Also see “Assembly of stop plugs” below.

• The

air

fi

lter should be clean and the cylinder cover

fi

tted when all adjustments are

made.

First adjust the L-needle, then the H-needle and

fi

nally the idling speed’s T-screw.

Idling speed = 2,800 rpm.

Summary of Contents for 241R

Page 1: ...Workshop manual 241R 241RJ English ...

Page 35: ...4 34 Centrifugal clutch ...

Page 49: ...6 48 Cylinder and piston ...

Page 59: ...58 8 List of tools ...

Page 62: ...2008W37 115 11 96 26 ...